There are many options when it comes to building or buying a CNC. First is price, they can range from $3,000 to hundreds of thousands. I first started my research on DIY CNC kits. I zeroed in on the Black Toe CNC: http://buildyourcnc.com/blackToe4x8.aspx. This is the most affordable kit I found. The good: it’s cheap and it is a 4’x8’ table. Approx. build cost: $3,000

The bad: a full MDF structure (these machines are under a lot of stress), the electronics looked a bit complicated (check out the installation videos, they seemed a bit scary to me), you still need to build a very sturdy table. The chain/wheel sprockets looked a little cheap to me.

The second DIY table I checked out was Joes's hybrid CNC: http://www.joescnc.com/themachines-hybrid.php. Approx. build cost: $4,000

Good: Has a lot of good feedback on www.CNCzone.com, the frame and X beam are aluminum; you can upgrade to get a full aluminum system.

Bad: the gantry is MDF, you have to pay $100 for his drawings and to access his forum that has all of the details of the build(which I did), its only 4’x4’, I wanted a 4’x8’ and was under the impression that the forum would give easy directions on how to modify the size to a 4’x8’ table. The forum didn’t really give good details on how to build the 4x8. I am sure if I wanted to spend many many hours scouring the forum I could have figured it out. My issue is I want to build snowboards and not become an expert at CNC machines.

Those were the only two true DIY kits that I found that offered a fairly complete kit. Maybe someone has experience with other kits?

I did a little bit of research on the BEAR CNC http://www.wedmfg.com/Bear-Home.html. Good: A good machine for a good price, the builder is a member of skibuilders.com. The bad: the lead time was longer then I wanted to wait for.

If you want to buy a new full aluminum 4’x8’ CNC machine the minimum price I could find is around $7,500. On top of that you still need to pay shipping, software and endless upgrade charges! That wasn’t an option for me because my budget was around $5,000.

I did come across a company here in Denver that allows you to use their CNC machine. Actually, it’s a full wood and metal shop that you pay a membership for. It is an awesome place! The only issue I had is the owner didn’t want me to make the CNC a production machine for my business. The machine is a first come first serve with no schedule so it would be difficult to be productive on his machine. It is still probably a good alternative to anyone who doesn’t have the money to buy a CNC machine.

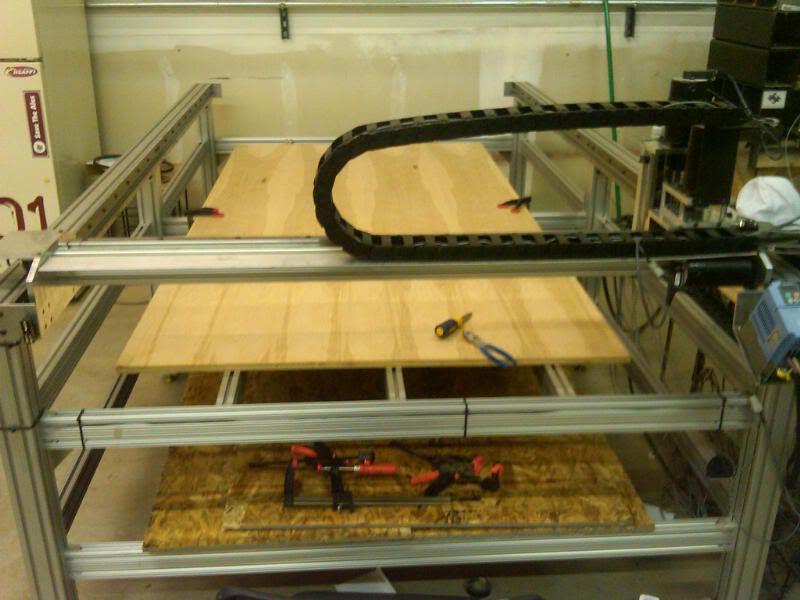

I ended up buying my machine off craigslist for $3,500 but missing some hardware and software that cost me $1,200. This machine was $12,000 new so I think I got a pretty good deal.

Software/Computer: There are 2 types of software you will need. The first controls the CNC machine. I thought I could use my laptop but it turns out laptops are not a good choice for CNC controllers because of their lack of port space. I ended up buying a good used computer for $200 that had 1 gig, 2 PCI slots and WIFI. I tried to go the DIY route again with the software. I ended up buying MACH3 for $175. Once I downloaded the installation guide I realized I was way over my head. Once again, I could have buried my head in the manual and figured it out but it would have taken me many weeks if not months to get the software working correctly. The issue is you have to calibrate the machine with this software and it’s not an easy job. So I ended up buying WINCNC for $1,200. The good: full support, the salesman took over my computer online and completely calibrated my CNC in a few hours. He was a great support to answer all of my questions. The bad: its $1,000 more than MACH3.

The second software you need is a CAM software. This software takes your CAD or drawings and coverts them into G-code. G-code is the language your CNC understands. I haven’t bought this software yet and hoping someone on here has some experience with a good choice. I don’t want to waste any more money! It was recommended to me to use either Vectric’s cut 3D/vcarve or visual mill, both cost around $900. Does anyone have any experience with either of these software packages in respect to snowboard cores? What programs are people using to accurately profile their cores?

If anyone has additional questions let me know.

FYI-slopes open in Colorado in about 4-6 weeks! Sweet!