Here was my old set up: viewtopic.php?t=2684

So two ski press it is, Mongo/spaceframe style, thanks Mongo!

Cutting metal.

Lots of metal.

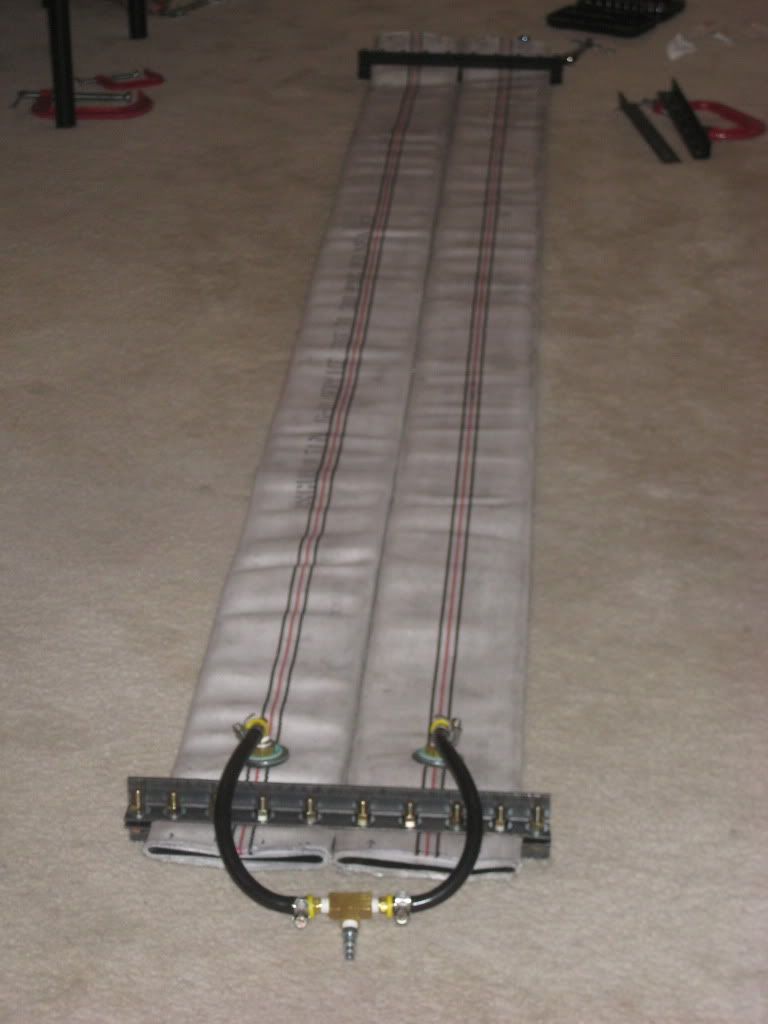

Two hose bladder. Leak proof without any sealant by the way.

1/16" alu cattrack, all cut by hand with a hacksaw...

Cattrack detail

Had a friend's dad who is a pro welder weld up my frame. Absolutely this many ( ) maths went into figuring out how strong my press would be, but I went with 3/16" steel tubing so I'm pretty sure it's over built.

Weld detail.

Painted, ran out of orange, whatever, at least it's all primed.

Trying something out I'm calling modular molds. I have three cambers, 35m regular camber, 35m reverse camber, and a flat camber mold, along with four tip/tail molds with varying amounts of rocker. All held together with threaded rod.

Also built an adjustable core profiling crib using aluminum shims, wayyyy too many holes.

To hold an adjustable top mold in the press I made up a little track underneath the top piece of MDF that the upper mold pieces slide on.

Upper mold block.

Upper mold tip/tail.

Still waiting on bungee to secure the cattrack.

But it holds at 40 psi!

Not too much of a void in the tip/tail sections, I'm ok with this.

Now I just need to build some skis, thinking about bamboo since I don't have a very good hardwood supply where I'm living and I found a good deal on bamboo floor boards (I'm sure everyone knows about cali bamboo by now, not sure if they're the best but they were easy to work with and relatively inexpensive from what I've gathered).

Any tips on core profile for bamboo? I've always used maple which I seem to recall is quite a bit stiffer.