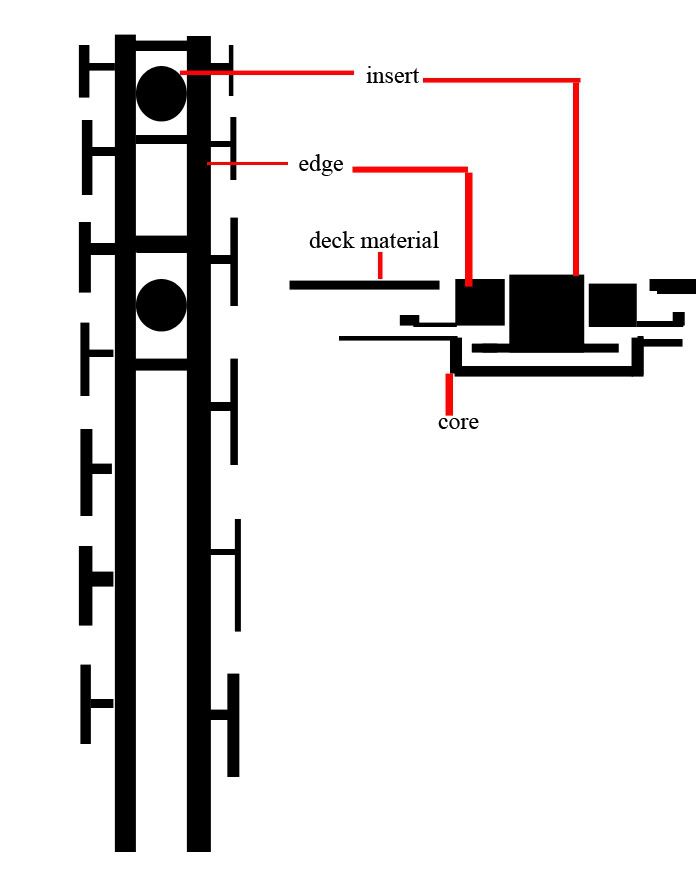

does anyone know where to get sliding inserts like those on capita snowboards? If so, are they individual or could you have 3 parallel tracks with multiple sliding inserts? That is, to allow for alpine and tele bindings.

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

That is one of the better ideas I've heard lately. Having a HDPE riser that fits your alpine bindings then having the tracks to move your tele pattern fore & aft would be pretty incredible.collin wrote:

Are the widths between the mounting holes on alpine and tele bindings the same? Could you actually swap bindings? I was thinking about using simple patern of inserts on the ski and mounting an HDPE plate with more inserts in it that match up to a binding.

Anybody remember "Ess var" alpine bindings maybe 10 years ago? They did the whole shift forward/backward thing with a fixed mount to the skis. I feel really old when I remember my friends "cool" skis one season being a pair of Hart bump skis with Ess var's.

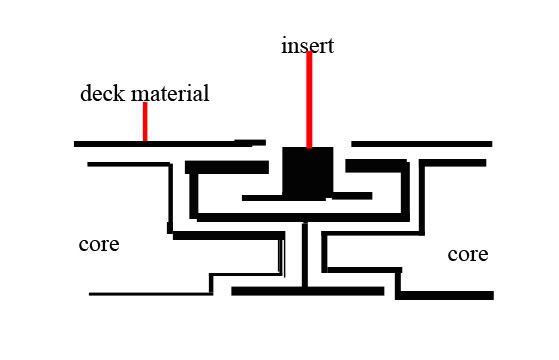

Yeah, no problem. Though I was just kinda guessing on the dimensions since I don't have any inserts, just playing around really. If somebody could tell me the distance between the two flat sides on the bottom of the insert, the diameter of the bottom (ie if the flat sides weren't there the diameter of the bottom flange), and the outside diameter of the threaded part.have you got a CAD drawing by any chance, collin?