Page 3 of 8

Posted: Thu Mar 03, 2011 6:40 pm

by Brazen

Posted: Fri Mar 04, 2011 2:25 am

by Idris

Very nice work

Posted: Fri Mar 04, 2011 3:33 am

by skidesmond

What's to freak out about? Looks perfect! What ever you're doing keep doing it.

Some times I think ski building is like golf in a way (at least the way I play). You hit a nice drive down the center of the fairway and not really sure how you did it. The next time you try to do the exact same thing and you end up deep in the rough..... Go figure.

Posted: Fri Mar 04, 2011 8:21 am

by chrismp

thats beautiful!

lets see those graphics!

btw, the board looks really thick at the contact points...whats your core profile thickness? or maybe its just the photo.

again, really nice work!

Posted: Fri Mar 04, 2011 1:16 pm

by Brazen

Thanks guys, nothing makes the long hours more worthwhile for me than people that KNOW giving you a thumbs-up. Chris, here's the graphic...I would have actually taken a shot of the board, but it already "leaked" out of my shop, my d'bag friends "Let me test that for you in Mammoth this weekend" You know...you probably have some too haha. It's a 165cm and the thickness was 7mm center, 7.5mm underfoot to 2.2mm at the tips, vds top and bottom, carbon fiber ON TOP and 19oz triax top and bottom, turned out 10mm underfoot so... it might be a little heavy. I'll know tomorrow

Posted: Sat Mar 05, 2011 3:17 pm

by Brazen

Here's the texts I got from Mammoth..."handles like a dream" "FAST!" "Edge holds super in crud" "Lots of compliments on the board" "Great pop out of turns!". It's hard to determine what to change from this type of feedback.

Posted: Sat Mar 05, 2011 4:30 pm

by skidesmond

Brazen wrote:Here's the texts I got from Mammoth..."handles like a dream" "FAST!" "Edge holds super in crud" "Lots of compliments on the board" "Great pop out of turns!". It's hard to determine what to change haha.

It's always great to get positive feedback from a fellow skier/boarder. Not to steal your thunder but today I got similar feedback from skis I made that I let our race director use for the day. And lets face it, it feeds the ego just a bit but mostly it tells you you're doing something right! Nice work!

Posted: Sun Mar 06, 2011 3:08 pm

by fa

hey Brazen, super clean finish

great to hear it rides nice, congrats!

Posted: Thu Mar 17, 2011 4:41 pm

by Brazen

Posted: Thu Mar 17, 2011 10:54 pm

by MontuckyMadman

Oh no!!

Ha ha sick.

they look real thick. Weird.

good job.

You should put some peiziolastic dampners in there.

Posted: Fri Apr 22, 2011 9:27 pm

by Brazen

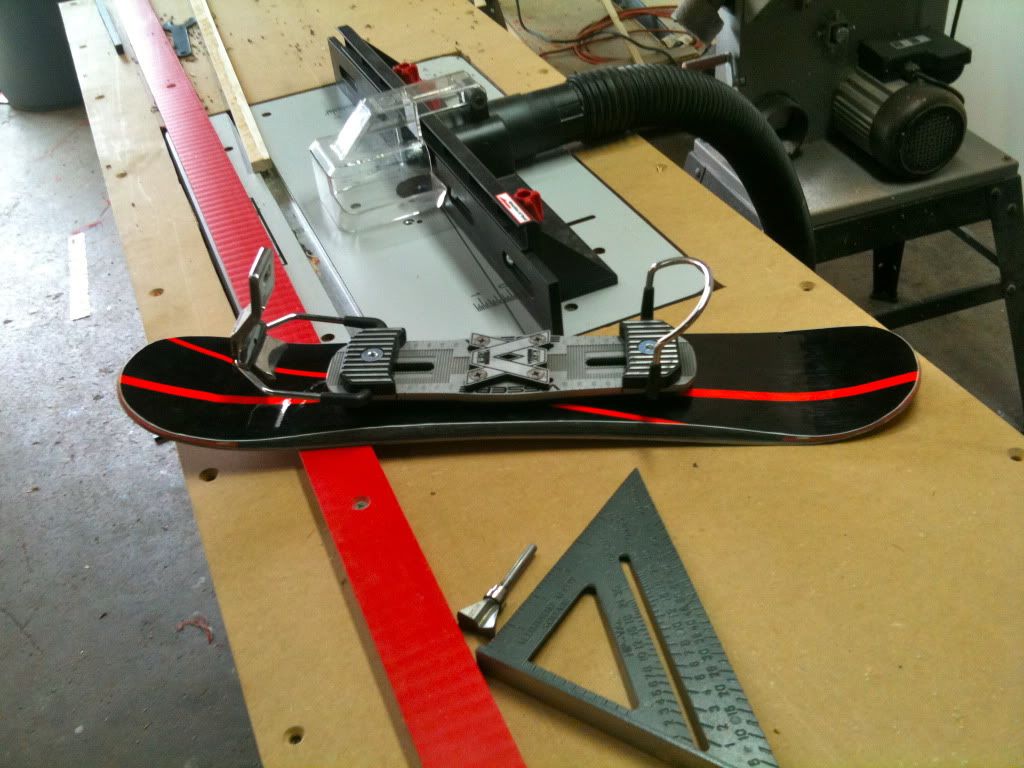

Better yet...

hehe, the new tooling rocks )

Posted: Sat Apr 23, 2011 1:13 am

by Richuk

Great - glad to see the new tooling is working as you like. It keeps the board pressed down and kills the vibration?

Posted: Sat Apr 23, 2011 5:13 am

by skidesmond

Super nice finish on that board! What did you use?

Posted: Sat Apr 23, 2011 5:17 am

by threeninethree

Is your cnc gantry fixed in the X, with the motion at the table? Nice design!

Posted: Sat Apr 23, 2011 11:01 am

by Brazen

Richuk, yeah! The router table modification I built works , well, perfectly. The soft rubber idler wheels press the board down even with the router bearing and keep the board from changing outward angle as well. I'm stoked!

SkiDesmond, Yeah, I really love the way the finish turned out as well. It's a 2 part linear polyurethane from TCP Global. Honestly though, I doubt if I'll ever do this type of finish again...I believe I've found a superior and less labor intensive way to go. We'll see haha

393, it is a fixed X...my long range idea for it is to put a large sanding drum on the Z axis for flex profiling. And thanks! That thing was a lot of work, and had me ready to throw it (and myself) off a cliff several times before I finally got it set up correctly haha.