"you building what? Are you mad?"

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

MontuckyMadman wrote:pretty sure the cpl is the compression molding application only.

why do they keep changing shit and confusing me. I just tell them to give me the same shit I always use.

Approximately how much time do I have before cpl epoxy start jelling?

MM PDF file saying 20 min under heat.. IIRC you mentioning one hour under heat in the press somewhere. What you would you recommend?

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

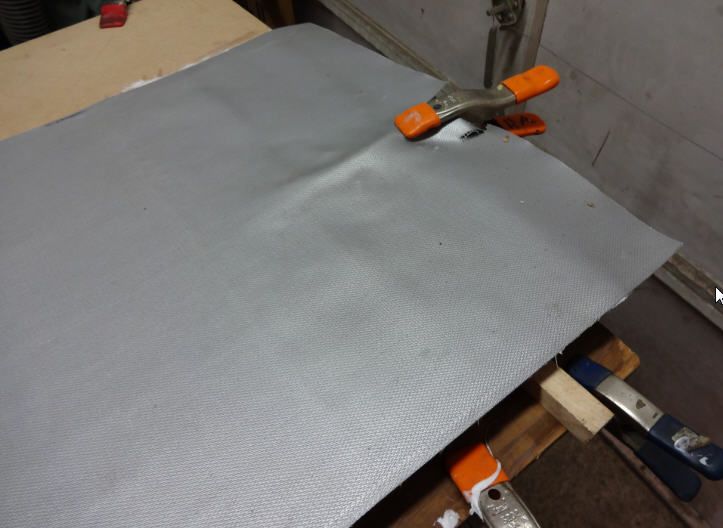

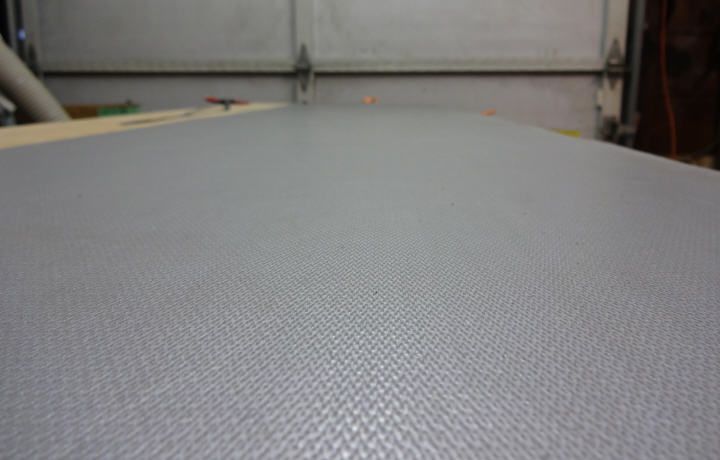

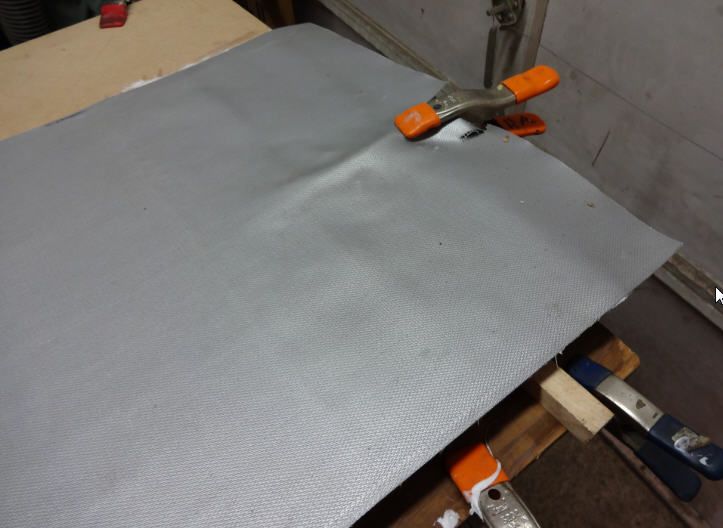

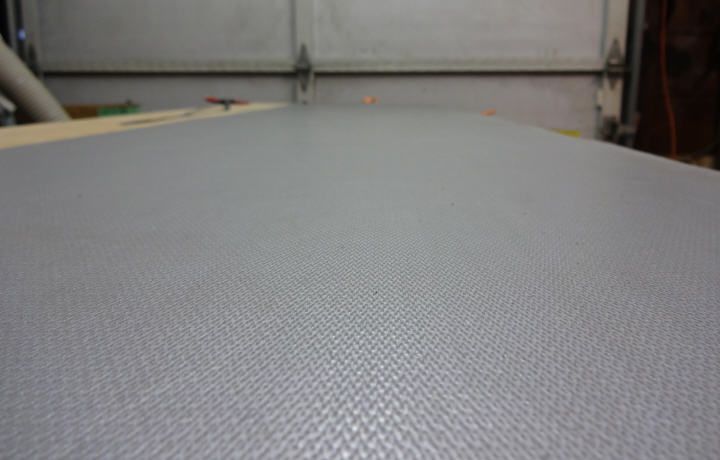

second blanket complete

a few pictures

better picture of bus connection. I use section of extension cord so unused wires used as anchor

same bus when blanket completed

couple views of the blanket surface

not sure if this problem, only time will tell. When blankets rolled small wrinkle and few small bubbles under outer skin. Maybe one part silicone in tubes was not the best choice. For our application in the press under pressure shouldn't be a problem

a few pictures

better picture of bus connection. I use section of extension cord so unused wires used as anchor

same bus when blanket completed

couple views of the blanket surface

not sure if this problem, only time will tell. When blankets rolled small wrinkle and few small bubbles under outer skin. Maybe one part silicone in tubes was not the best choice. For our application in the press under pressure shouldn't be a problem

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

My professionally made blanket will crease like that if folded or rolled too tight. Doesn't seem to be a problem, just don't leave it folded/rolled too tight.

Mine doesn't have air bubbles. They could be a problem. I think the pressure in the press will flatten them out which might promote delam of the blankets as they try and spread. They may blow out the side of the blanket and then shouldn't be an issue anymore.

Mine doesn't have air bubbles. They could be a problem. I think the pressure in the press will flatten them out which might promote delam of the blankets as they try and spread. They may blow out the side of the blanket and then shouldn't be an issue anymore.

Don't wait up, I'm off to kill Summer....

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

1-st blanket have big bubbles. On my first run they did not get inflated. Will see. Maybe poke some holes. Maybe use thicker metal for cassette and for blankets I'm getting 22gauge steel for cassette and maybe 24gauge for blankets instead of 0.016" aluminium I planned for.MontuckyMadman wrote:Those bubbles ade pretty small but if they were bigger it wouod tranlate to the length of the laminate and leave a wave.

Been there done that.

Your good to go. Press somthing already!!!

Unfortunately I'm not ready yet. Need to do a few more things. Can't wait. hopefully this summer get to press couple pairs

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

fire up blankets and the controller. Working very nicely, well I have nothing to compare to

don't know if it good, bad or ugly. Here is the results:

My goal was to test the temperature and it consistency, Only one bottom blanket tested. Without cassette. only blanket and 0.016"aluminum. Cardboard between blankets no pressure was applied. Probably good 3 hours blanket was on. I set temperature on the controller 150°F and used meat thermometer to test actual temperature. With 1°f differential temperature on the blankets fluctuate approximately 5 to 8° in either direction from set point. I did not noticed any difference between temperature reading in the middle and in the tip/tale area. So total temperature fluctuation 10 to 18° within each cycle. I will be getting 22gauge galvanized steel for the cassette if anything it should smooth out temperature fluctuation.

don't know if it good, bad or ugly. Here is the results:

My goal was to test the temperature and it consistency, Only one bottom blanket tested. Without cassette. only blanket and 0.016"aluminum. Cardboard between blankets no pressure was applied. Probably good 3 hours blanket was on. I set temperature on the controller 150°F and used meat thermometer to test actual temperature. With 1°f differential temperature on the blankets fluctuate approximately 5 to 8° in either direction from set point. I did not noticed any difference between temperature reading in the middle and in the tip/tale area. So total temperature fluctuation 10 to 18° within each cycle. I will be getting 22gauge galvanized steel for the cassette if anything it should smooth out temperature fluctuation.

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

played little bit more with controller today.

Inserted metal for cassette t help reduce fluctuations to 10°f. Tips running consistently hotter by 10°f. Entire cycle from point where controller shut off the blanket about 4 to 6 min. blankets actually on for about a 1.5 to 2 min.

Also difference in fluctuation of the temperatures I mentioned is between controller and meat thermometer actual fluctuation on the controller 3 to 4° above and below setpoint

doing it first time I have nothing to compare. Hope somebody can post their readout.

Inserted metal for cassette t help reduce fluctuations to 10°f. Tips running consistently hotter by 10°f. Entire cycle from point where controller shut off the blanket about 4 to 6 min. blankets actually on for about a 1.5 to 2 min.

Also difference in fluctuation of the temperatures I mentioned is between controller and meat thermometer actual fluctuation on the controller 3 to 4° above and below setpoint

doing it first time I have nothing to compare. Hope somebody can post their readout.

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

first set of cores is ready to go. While looking nice in the picture I had so many problems and mistakes  was ready to give up twice. Have zero expectation on this pair will be surprised if it ever sees the snow lol

was ready to give up twice. Have zero expectation on this pair will be surprised if it ever sees the snow lol

live and learn. Probably by far best skill to have go into this project would be woodworking

back on truck to press next week

live and learn. Probably by far best skill to have go into this project would be woodworking

back on truck to press next week

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA