Heat Blanket - Bottom Only

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

Hi doughboyshredder,

The upper mold section of my press raises and lowers. So, I actually lay-up my skis in the press, rather than outside of the press. I find that I can eliminate many of the common alignment/shifting woes by doing this. If I were to pre-heat the press, I'd be laying up on a hot surface and my resin would be going off even before I got the core in place. The downside to laying up inside the press is that I have to wait and let the press cool of before I stick in a second ski. Pressing two at once is out for me... I get stressed out enough just doing one at a time.

G-man

The upper mold section of my press raises and lowers. So, I actually lay-up my skis in the press, rather than outside of the press. I find that I can eliminate many of the common alignment/shifting woes by doing this. If I were to pre-heat the press, I'd be laying up on a hot surface and my resin would be going off even before I got the core in place. The downside to laying up inside the press is that I have to wait and let the press cool of before I stick in a second ski. Pressing two at once is out for me... I get stressed out enough just doing one at a time.

G-man

I havent gotten time to read everything in this but I have had a couple of different things happen with camber and bottom heating.

Scenario 1

My first couple of pairs I had the press set at 70 degrees F during lay up, and then ramped the heat up to 170 with no stops. Let the ski cure for 45-60 min and took it out with no cooling. The camber of the ski was almost right on.

Scenario 2

A friend who I build with, ramped his temp up very slowly. let the ski sit at full temp for about an hour I think and then let it cool in the mold. The Ski came out with more camber than the mold had.

Scenario 3

Then one evening, In my garage, I didnt bother warming up the bottom mold, and had the base and edges set up in it for a few days prior. The mold edges and base where at about 41 degrees during lay up. I then put it all in the press, inflated the bag, and ramped the heat right up to 170. When I took the ski out of the mold it came out with rocker!!!!

here is my theory on this.

If the edges have a greater coeficient of thermal expansion that the other materials (mainly the fiberglass). when the edges heat up to 140 or 150 degrees along with the whole ski before the epoxy cures, they are going to expand more than the rest of the materials. and once the epoxy is cured they are set relative to the rest of the ski. When you pull them out they decrease in lenght and give it camber. (scenario 2)

If the edges dont get time to fully heat (center or core of edge is at maybe 60 degrees while the surface is just pushing cure temp of around 150) and the epoxy cures, the edges will not have as much relative expansion as the rest of the ski. when the ski is allowed to cure, the top layer of fiberglass and other matirials will contract while the edges wont contract as much, causing rocker. (scenario 3).

From my personal experience, if you start at a warm temperature (70 deg for me) and ramp up quickly all o0f the materials will have equal relative expansions and the ski should come out with the same shape as the mold.

I think if you have a top and bottom blanket you could still have your ski come out with messed up camber (relative th the mold) if you heat the ski too slowly (increased camber) or start it at too low of a temp and ramp it very quickly (rocker).

Other influences on camber and rocker will be the design of your press. If you calc (or measure by hand) the deflection of an open beam press, you may find that your mold in fact deflects. say you have 1cm of deflection, your mold that originally had 1cm of camber is now flat. Inh this case slow ramping is good for you because it will give your ski the camber it lost with the deflection of the mold.

Scenario 1

My first couple of pairs I had the press set at 70 degrees F during lay up, and then ramped the heat up to 170 with no stops. Let the ski cure for 45-60 min and took it out with no cooling. The camber of the ski was almost right on.

Scenario 2

A friend who I build with, ramped his temp up very slowly. let the ski sit at full temp for about an hour I think and then let it cool in the mold. The Ski came out with more camber than the mold had.

Scenario 3

Then one evening, In my garage, I didnt bother warming up the bottom mold, and had the base and edges set up in it for a few days prior. The mold edges and base where at about 41 degrees during lay up. I then put it all in the press, inflated the bag, and ramped the heat right up to 170. When I took the ski out of the mold it came out with rocker!!!!

here is my theory on this.

If the edges have a greater coeficient of thermal expansion that the other materials (mainly the fiberglass). when the edges heat up to 140 or 150 degrees along with the whole ski before the epoxy cures, they are going to expand more than the rest of the materials. and once the epoxy is cured they are set relative to the rest of the ski. When you pull them out they decrease in lenght and give it camber. (scenario 2)

If the edges dont get time to fully heat (center or core of edge is at maybe 60 degrees while the surface is just pushing cure temp of around 150) and the epoxy cures, the edges will not have as much relative expansion as the rest of the ski. when the ski is allowed to cure, the top layer of fiberglass and other matirials will contract while the edges wont contract as much, causing rocker. (scenario 3).

From my personal experience, if you start at a warm temperature (70 deg for me) and ramp up quickly all o0f the materials will have equal relative expansions and the ski should come out with the same shape as the mold.

I think if you have a top and bottom blanket you could still have your ski come out with messed up camber (relative th the mold) if you heat the ski too slowly (increased camber) or start it at too low of a temp and ramp it very quickly (rocker).

Other influences on camber and rocker will be the design of your press. If you calc (or measure by hand) the deflection of an open beam press, you may find that your mold in fact deflects. say you have 1cm of deflection, your mold that originally had 1cm of camber is now flat. Inh this case slow ramping is good for you because it will give your ski the camber it lost with the deflection of the mold.

Brian

Figure I should add my first experience.

pressed my first ski last night. Now on to getting it to break, then pressing my first pretty pair.

Anyway, flat mold, tip rocker of around 1.5cm x 15cm. Pneumatic press, using aluminum cassettes.

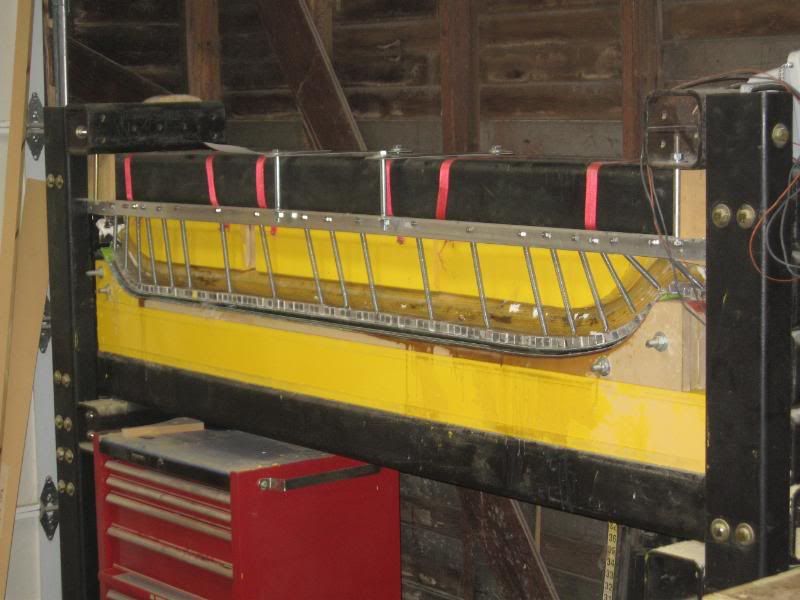

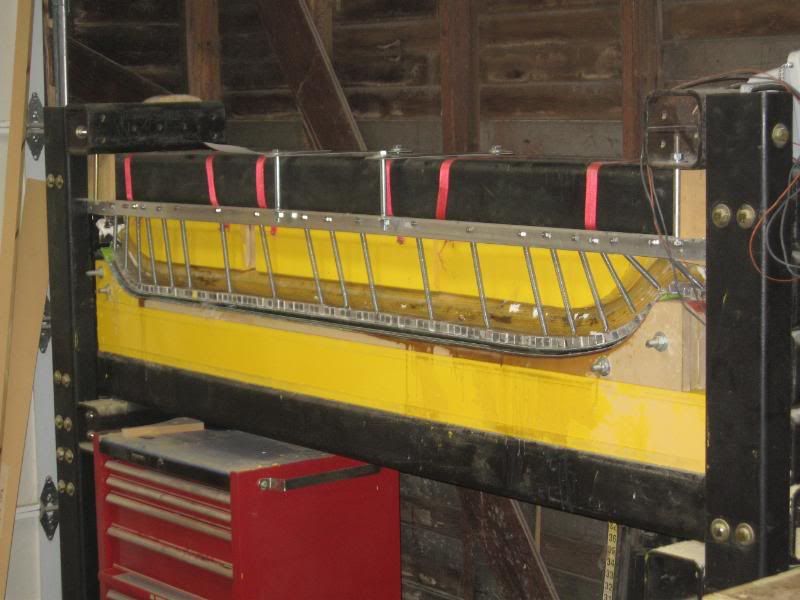

Set up on the bottom was mold, hardboard, heat blanket, 1/16 aluminum sheet, 1/16 aluminum sheet, materials, 1/16 aluminum sheet, cat track, hose, top mold.

So only one heat blanket, on the bottom.

I am using QCM 0043 and 0032 I think. Pressing at 81 degrees C.

Before laying up the ski, I put the top section of the cassette in the press with the heat on at 81 degrees C.

layed up the ski, top the heated top cassette out of the press, threw the ski in the press, with the temp already at 81 degrees C, inflated the hose to 70 psi, and left for two hours.

Came back and ski was obviously done.

Pulled it out, was impatient and knowing I would only be using this ski to test some stuff, I cut it out on the spot. I spray water on it to keep the fiberglass fibers from going anywhere and it was going from liquid to vapor while I cut the flash off. Blade I used worked fine, but I had a hard time in the tips and tails. I do a 3/4 wrap and because of this, I had a hard time differentiating between where the base material ended because the tips have alot of VDS in them. Anyway...

No delams, look great. Although I think I used way to much epoxy (sort of went overboard....) so they are a bit heavy.

ANYWAY, went back today and set them in the mold.

Tip and tails are exact, perfect fit back in the mold, including the amount of rocker I had set up.

Underfoot there is about 5-7mm of camber.

I am pretty stoked.

Now on to doing a few things with the sidewalls and mess with them, then on to other skis.

Few pics. I will have a huge post when my first pair comes out hopefully next week.

As you can see in the right side of the mold....epoxy was everywhere.

But yeah, I am pretty pleased with just one blanket. Eventually I think I am going to get rid of this press and make one that is 2 skis wide, and when I do that I would likely get both a top and bottom heater. But this works for now.

pressed my first ski last night. Now on to getting it to break, then pressing my first pretty pair.

Anyway, flat mold, tip rocker of around 1.5cm x 15cm. Pneumatic press, using aluminum cassettes.

Set up on the bottom was mold, hardboard, heat blanket, 1/16 aluminum sheet, 1/16 aluminum sheet, materials, 1/16 aluminum sheet, cat track, hose, top mold.

So only one heat blanket, on the bottom.

I am using QCM 0043 and 0032 I think. Pressing at 81 degrees C.

Before laying up the ski, I put the top section of the cassette in the press with the heat on at 81 degrees C.

layed up the ski, top the heated top cassette out of the press, threw the ski in the press, with the temp already at 81 degrees C, inflated the hose to 70 psi, and left for two hours.

Came back and ski was obviously done.

Pulled it out, was impatient and knowing I would only be using this ski to test some stuff, I cut it out on the spot. I spray water on it to keep the fiberglass fibers from going anywhere and it was going from liquid to vapor while I cut the flash off. Blade I used worked fine, but I had a hard time in the tips and tails. I do a 3/4 wrap and because of this, I had a hard time differentiating between where the base material ended because the tips have alot of VDS in them. Anyway...

No delams, look great. Although I think I used way to much epoxy (sort of went overboard....) so they are a bit heavy.

ANYWAY, went back today and set them in the mold.

Tip and tails are exact, perfect fit back in the mold, including the amount of rocker I had set up.

Underfoot there is about 5-7mm of camber.

I am pretty stoked.

Now on to doing a few things with the sidewalls and mess with them, then on to other skis.

Few pics. I will have a huge post when my first pair comes out hopefully next week.

As you can see in the right side of the mold....epoxy was everywhere.

But yeah, I am pretty pleased with just one blanket. Eventually I think I am going to get rid of this press and make one that is 2 skis wide, and when I do that I would likely get both a top and bottom heater. But this works for now.