update on press progress

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

can't believe you haven't used mdf in all your building.

I can make radius tip pieces on my Eastman cutter machine out of plastic and send them to you.

Perfect radius. For my tip and tail I am using 26 cm R

http://www.skibuilders.com/phpBB2/viewtopic.php?t=1019

I can make radius tip pieces on my Eastman cutter machine out of plastic and send them to you.

Perfect radius. For my tip and tail I am using 26 cm R

http://www.skibuilders.com/phpBB2/viewtopic.php?t=1019

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

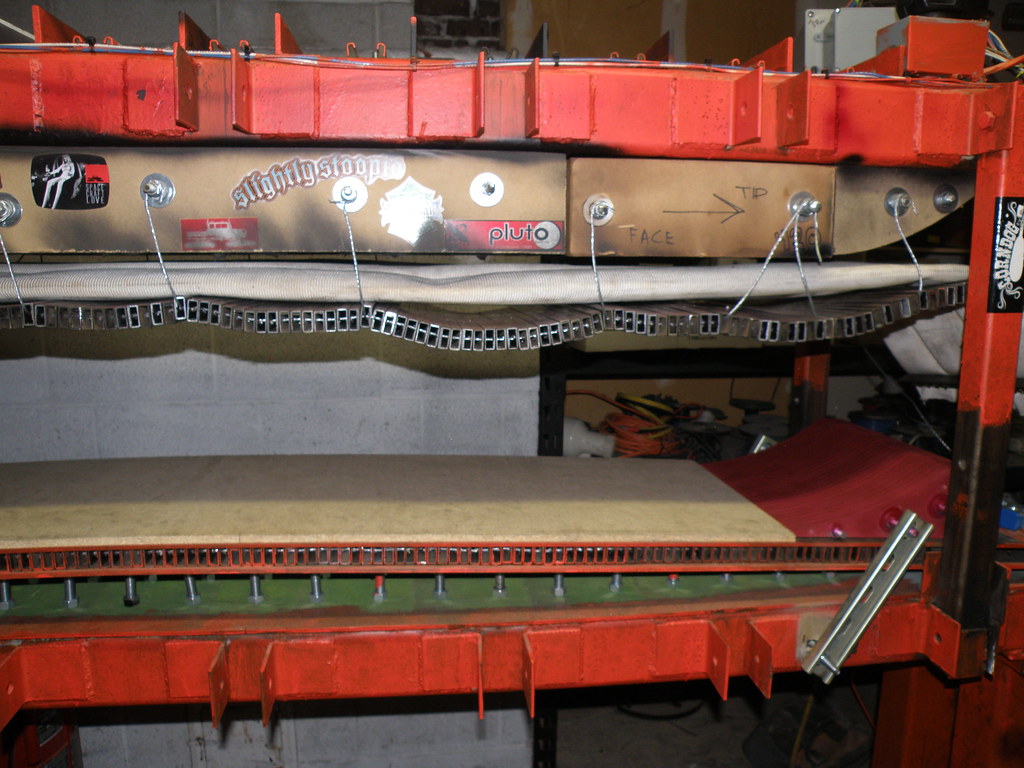

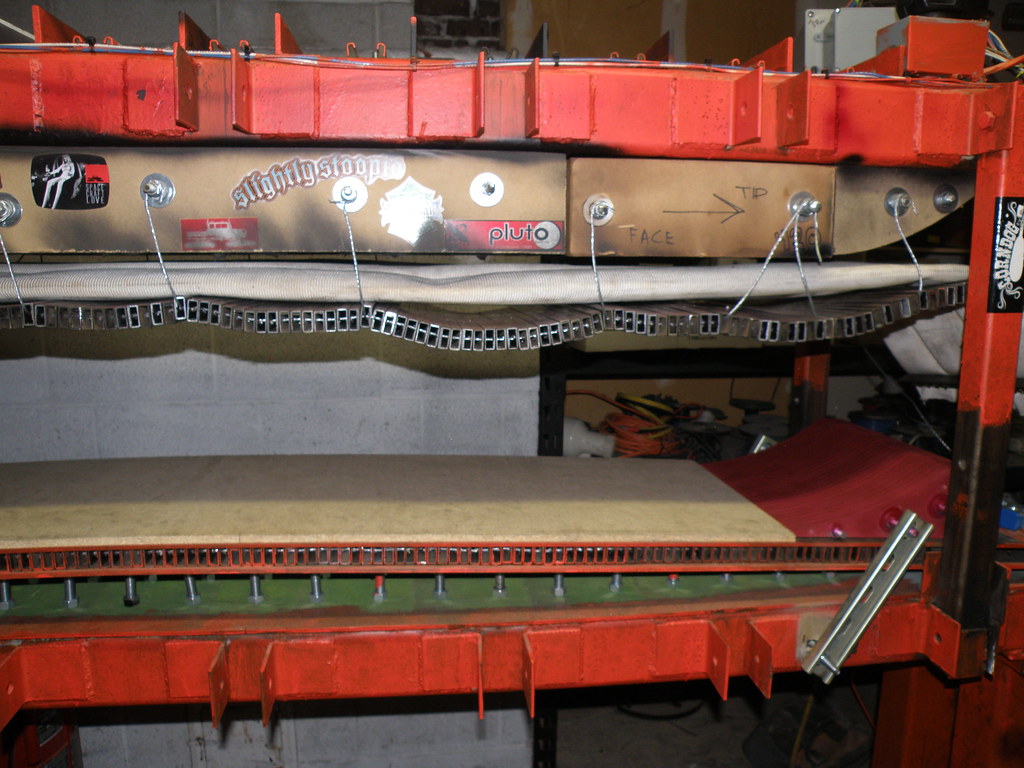

ah, the sweet smell of success. So stoked. Pressure tested it to 50 plus psi and it didn't so much as make a squeak. The carriage bolts didn't even budge a 64th of an inch. Hell the brace pins didn't even seem to experience any force. The only issues I had were that the air bag fittings got scrunched up against the block and one little section has to be replaced. To solve this i need to flip the bags over. The slotted adjustments for the tip and tail block didn't work as well as necessary. With the bolts cranked down with a 1/2" ratchet they still slipped. I mean CRANKED down. Easy fix, just have to drill angle iron for the right placement. Also, it looks like I am going to need to shim the tip and tail area with about a 1/2" of material. I am just going to place a few sheets of vener above the air bags in the tip and tail. As far as I am concerned it's a success because there was zero visible deflection. Stoked.

I couldn't have done this without the support and knowledge provided by this website and the forum members. Thank You all.

I couldn't have done this without the support and knowledge provided by this website and the forum members. Thank You all.

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm