Ski Haus ski builders

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

if no cat track, use a thicker gage sheet on top,

the bag will bend the sheet if its thin, therefore negating any gaps you rout out on your sidewall

either that, or maybe something wrinkled in that spot? or epoxy could have pooled and hardened too quick and caused the base to be higher than the bottom sheet?

the bag will bend the sheet if its thin, therefore negating any gaps you rout out on your sidewall

either that, or maybe something wrinkled in that spot? or epoxy could have pooled and hardened too quick and caused the base to be higher than the bottom sheet?

Doug

-

Telemark Mark

- Posts: 20

- Joined: Mon Mar 05, 2007 8:38 pm

Spacer???

I've had issues with concave bases as well. I vacuum mold my skis...........and I think my concave bases are the result of not routering out the channel for the edge windows to sit into the core. I have been using simple posterboard to fill the "gap" with good results so far. I just take posterboard.........cut it to fit in between the edge windows........and perforate it with a hole puncher (although I don't know that this step is crucial....just thought it might help with epoxy bondage). The posterboard soaks out very well with epoxy........and seems to adhere just fine.

Now the finished skis come out just slightly concave. I think that the VDS strips are the reason for this. Edge windows + VDS strips equals quite a bit of "extra" space that the base can be sucked up into.

I'm thinking of doubling up on posterboard for a pair to see what happens.

Another Idea I had was to get thicker base material (maybe up to .5mm thicker) so that it extends past the bottom-most part of the edges a little bit.

Then I could grind/sand all I wanted and get a truly flat base.

Thoughts?

Now the finished skis come out just slightly concave. I think that the VDS strips are the reason for this. Edge windows + VDS strips equals quite a bit of "extra" space that the base can be sucked up into.

I'm thinking of doubling up on posterboard for a pair to see what happens.

Another Idea I had was to get thicker base material (maybe up to .5mm thicker) so that it extends past the bottom-most part of the edges a little bit.

Then I could grind/sand all I wanted and get a truly flat base.

Thoughts?

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

That's right, I used the router to "plane" the base of the core, it was nearly perfectly flat.

I don't see how not using a cat track would negate the channel routed for the edges. Sure, the hose pushes the sheet metal down around the sides of the ski a bit, but this shouldn't cause the sidewall to push down I wouldn't think.

I don't see how not using a cat track would negate the channel routed for the edges. Sure, the hose pushes the sheet metal down around the sides of the ski a bit, but this shouldn't cause the sidewall to push down I wouldn't think.

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

Not using a cat track is your problem.KevyWevy wrote:no, we aren't using a cat track. just the ski then thin sheet metal and then the hose.

the sidewalls were attached to the core before it was profiled.

without a cat track the edges are receiving slightly more pressure and causing your concavity.

There is a reason that EVERY builder is using a cat track.

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

sorry, I should have specified, that I meant every manufacturer using a pneumatic press, that is not using a cnc machined hard cassette. Also, if you look through here and graf, you will not find a single pneumatic press that is functioning succesfully without a cat track.

But, really, I don't know s hit. It's just black magic causing the bases to be concave.

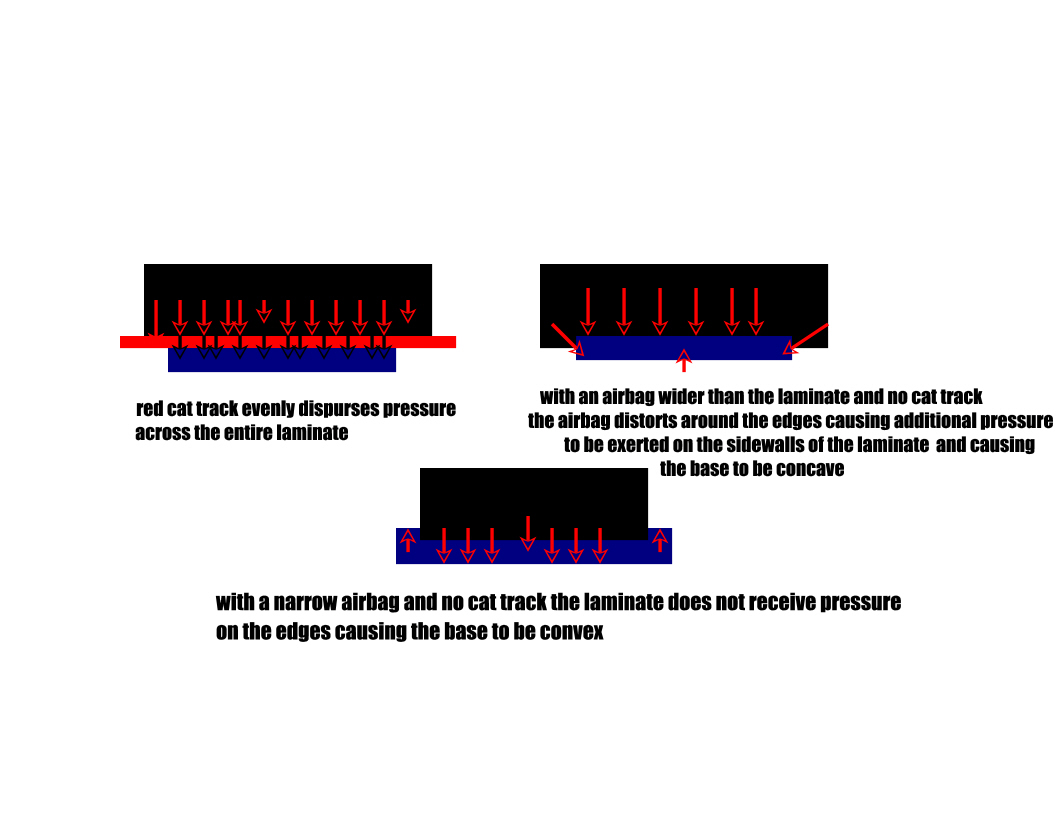

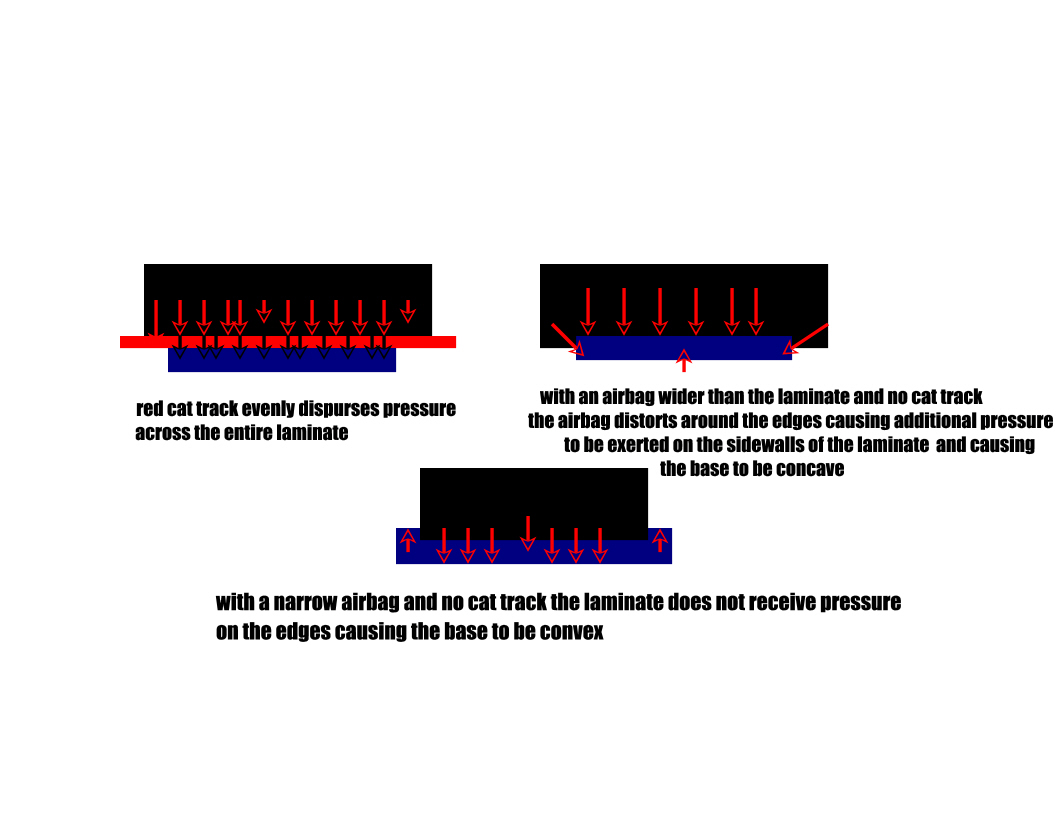

Think it out logically. Without the cat track to disperse the pressure it is physically impossible to ensure an even pressure across the surface of the laminate. If the surface area of the laminate is more than the surface area of the airbage you will have a convex base, because there is higher pressure towards the middle. If the surface area of the laminate is less than the surface area of the airbag you will have a concave base, because of the added pressure on the edges of the laminates. This is simple physics.

But, again, I really don't know s hit. I didn't think the plane would take off, so .......................... like I said, what do I know.

But, really, I don't know s hit. It's just black magic causing the bases to be concave.

Think it out logically. Without the cat track to disperse the pressure it is physically impossible to ensure an even pressure across the surface of the laminate. If the surface area of the laminate is more than the surface area of the airbage you will have a convex base, because there is higher pressure towards the middle. If the surface area of the laminate is less than the surface area of the airbag you will have a concave base, because of the added pressure on the edges of the laminates. This is simple physics.

But, again, I really don't know s hit. I didn't think the plane would take off, so .......................... like I said, what do I know.

I dont use a cat track and I get good results. I also have a super flat press and mold, and make sure I rout the relief in my core enough.

There are alot of reasons why a ski may not come out flat, Using a cat track will very likely help make a flat ski. But, a cat track with a convex bottom mold is still very likely to produce a concave ski. So before you build a cat track, make sure you have a flat base mold and press base.

I grew up in albany NY and would visit the line ski factory when they were still manufacturing in albany. They were producing hundreds of skis (mainly snowlerblades at first) with a capped sonstruction using an airbag and no cat track. You obviously cant press a capped ski with a cat track. The "simple physics" wont allow it to work.

An airbag without a cat track will work.

There are alot of reasons why a ski may not come out flat, Using a cat track will very likely help make a flat ski. But, a cat track with a convex bottom mold is still very likely to produce a concave ski. So before you build a cat track, make sure you have a flat base mold and press base.

I grew up in albany NY and would visit the line ski factory when they were still manufacturing in albany. They were producing hundreds of skis (mainly snowlerblades at first) with a capped sonstruction using an airbag and no cat track. You obviously cant press a capped ski with a cat track. The "simple physics" wont allow it to work.

An airbag without a cat track will work.

Brian

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

Is this interweb sarcasm?Three31 wrote:You obviously cant press a capped ski with a cat track. The "simple physics" wont allow it to work.

Is a capped ski made by having the airbag wrap around the sides and laminate the topsheet to the core/sidewalls?

I thought it was in a mold, not a cassette, but a mold.

If the airbag is evenly distributed over the entire laminate why would the edges receive more pressure? Perhaps its just that the base buckles there and presses the tines into the base material slightly.

I could see if the bag wasn't evenly distributed how it would only press down on the middle of the ski and cause cocave base.

I took honers physics in high school, lots of word problems and math that took over a page in my trapperkeeper to solve.

Sorry if I was being sarcastic, I dont mean to be a jerk.

At the end I was just trying to tell you about what I saw in a production shop. I dont remember ever seeing a machined top mold, just a wide airbag that wraped over the sides to make the cap. Tio get a wide bladder see "Bladder Material" in equipment and tools http://www.skibuilders.com/phpBB2/viewtopic.php?t=1653.

I may be wrong about how they pressed their skis, It was almost ten years ago.

At the end I was just trying to tell you about what I saw in a production shop. I dont remember ever seeing a machined top mold, just a wide airbag that wraped over the sides to make the cap. Tio get a wide bladder see "Bladder Material" in equipment and tools http://www.skibuilders.com/phpBB2/viewtopic.php?t=1653.

I may be wrong about how they pressed their skis, It was almost ten years ago.

Brian

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

All of the cap boards that I have built (hundreds) were built using a cnc machined cassette with the cap shaped in the top plate. I don't know how you would build a cap construction without a top plate. The airbag would not form properly around the sides in my experience.

Three 31, what pressure do you press at? And are you building narrow, or wide skis?

Montucky Madman, I think that if the airbag is wider than the laminate there will be a slight additional pressure on the edges, because of the distortion of the airbags.

Three 31, what pressure do you press at? And are you building narrow, or wide skis?

Montucky Madman, I think that if the airbag is wider than the laminate there will be a slight additional pressure on the edges, because of the distortion of the airbags.

Okay, I am probably wrong about using an air bag to make a capped ski. Sorry.

I press at about 70 psi. Ive made skis ranging from 98 mm to 130 mm under foot.

For the most part they have come out fairly flat. The last pair I made this week I think the core shifted so the edges were not in the relief and they came out concave.

I press at about 70 psi. Ive made skis ranging from 98 mm to 130 mm under foot.

For the most part they have come out fairly flat. The last pair I made this week I think the core shifted so the edges were not in the relief and they came out concave.

Brian

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

"Simple physics" would say that the airbag alone would give you the most uniform pressure distribution, since it is a flexible skin with a uniform air pressure inside.

I understand that the airbag bends around the sides so you get some side force pushing on the corners of the sidewalls. But how this would cause a concave base still makes no sense to me. You still have most of the pressure on the top of the ski, so it should really be the bottom mold only that could cause concavity. If your bottom mold was totally flat, how would pushing on the sides cause the middle to rise?

I understand that the airbag bends around the sides so you get some side force pushing on the corners of the sidewalls. But how this would cause a concave base still makes no sense to me. You still have most of the pressure on the top of the ski, so it should really be the bottom mold only that could cause concavity. If your bottom mold was totally flat, how would pushing on the sides cause the middle to rise?

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

That statement makes absolutely no sense at all. The hose guarantees an even pressure, since its just the air pressure directly.doughboyshredder wrote: Think it out logically. Without the cat track to disperse the pressure it is physically impossible to ensure an even pressure across the surface of the laminate.