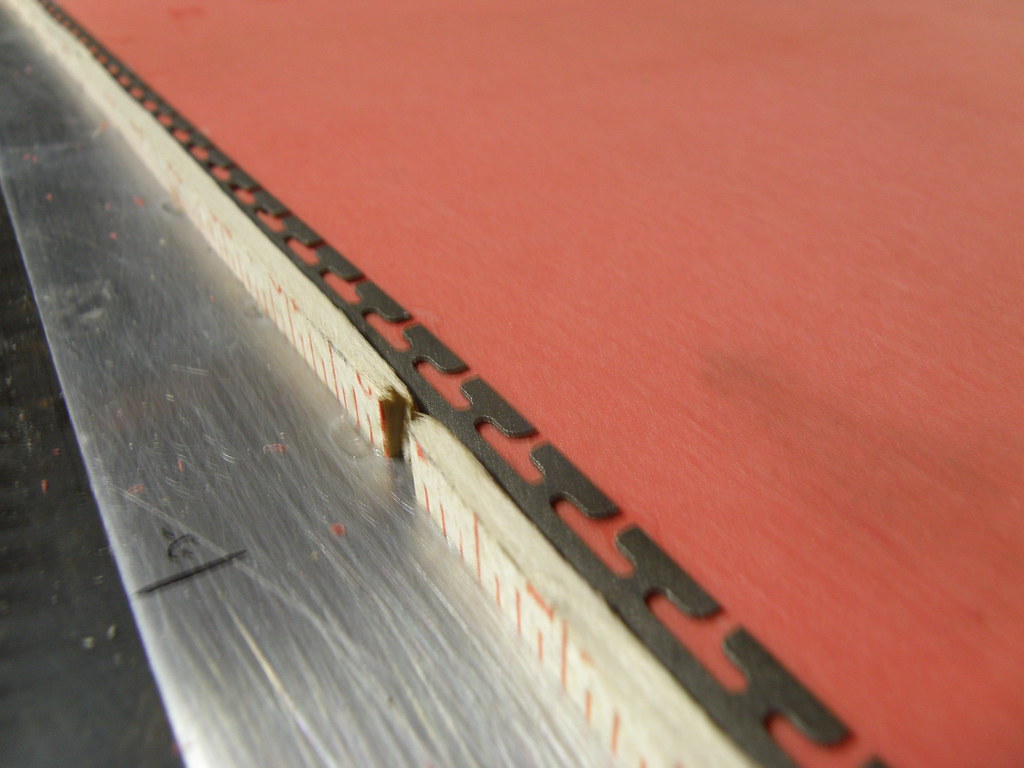

Basically the sidecut is radiused from the contact point to the insert pack, then straight to the center point.

This was a mistake on the first board that happened because of my dowel placement. But, it worked. really good.

This is a 166 semi twin

Running length is 126 cm.

Waist is 26.7

Sidecut radius 8.5 / 9 / 8.5

Tail is 2 cm shorter than the tip.

Layup is 20oz triax, 3 oz cf reinforcement, vds, core, sidewalls, kevlar, 20 oz triax, topsheet.

CF is in a x between the bindings. Kevlar runs full length vertically.