I don’t remember all the weights, and some may be off as well

Core + tip and tale material, edges and sidewalls weighed 1462grams

aprox 600grams of fiberglass

720grams of epoxy/hardener

16grams of rubber strips

2grams of fortune cookie fortune

top sheet and base I don’t remember the weights, it think they were around 4-500 each

Total weight for the board (yes I’m switching to imperial) was about 7.2lbs before the trimming, it weighs about 5.5 now, we still have some more material to remove, drill out the inserts, base grind etc etc

We used QCM's 032 and 049 epoxy and hardener pressing for 34min @ 80psi. The press was warmed up about an hour pre pressing to 160ish, when we put it in we ramped it to 183~ for the 34min

Being we were gitty as 13year old school girls we pulled it out right away and let it cool on a table for maybe 10min before doing some of the rough finishing.

No its not a full length core, yes the sidewalls are made from 3/16th thick tip/tail material. We got a great coverage with the epoxy aside from 2 spots on the base near the edges which I’m going to just fudge some epoxy in next time we press a board to help avoid delam. However for the first board and being it took maybe 4 hours from pulling the core from the shelf to where it sits now I’m pretty damn happy.

Also the base was an experiment with seeing if we can stain the cores. Looks like we can if we let it dry for more than 10hours, epoxy made the stain run, oh well.

Anyways here is some photos, possibly not in the correct order

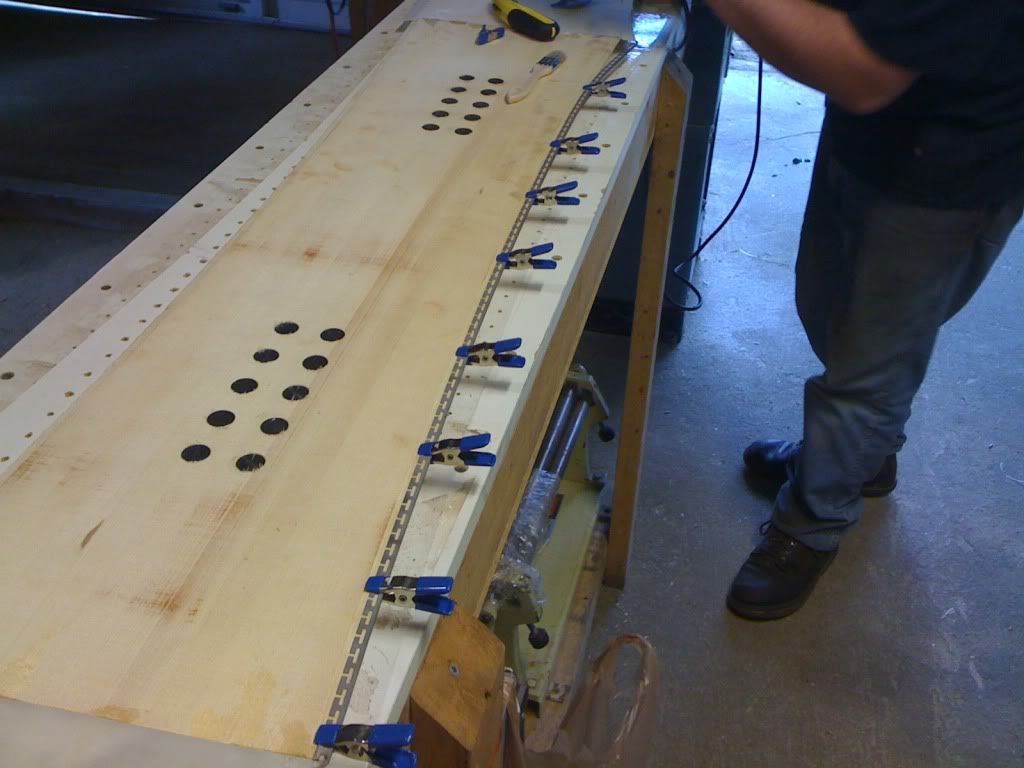

Tacking the edges down

Clamps, lots of them

ohhhh the excitement

The stain experiment

start of the layup

biax glass on the base, right about now I’m starting to second guess if we mixed enough epoxy

Glass up top

In the press

34min later.. voila

Rough finished, with friends daughter laying claim to it, regardless of it being to large

Base along with the bleeding stain

That’s where it’s at now, we need some router bits to finish the sidewalls and have to make a template so we can do the tips other than 'by eye'

A friend has access to a base grinder so in a week or so this should be done.

Ill post up more as this one is finished and we start the other 7 we have to make for friends.

-Jacob