Page 1 of 3

DXF for profiling crib?

Posted: Mon Aug 23, 2010 12:31 pm

by a.badner

Does any one have a dxf file for a planing crib?

I just found a really cheao cnc place and theyre giving me a special for this week and i want to get it out fast.

Thank you

Posted: Tue Aug 24, 2010 9:25 am

by a.badner

ARG,,, ill just make one.

Posted: Tue Aug 24, 2010 10:48 am

by a.badner

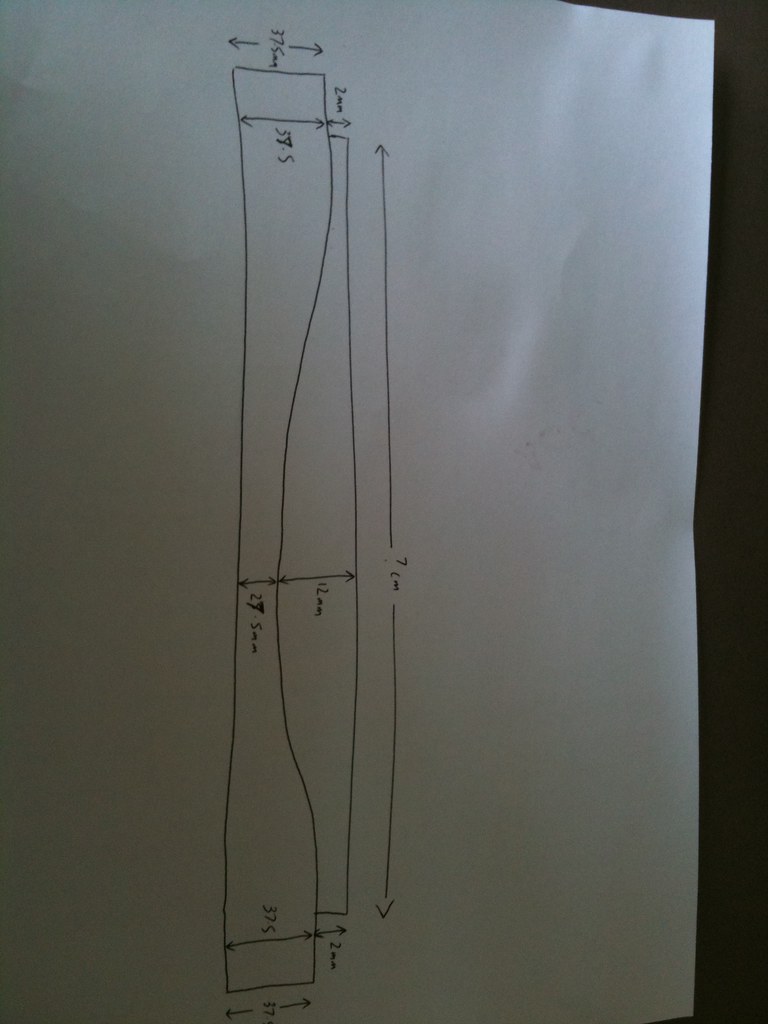

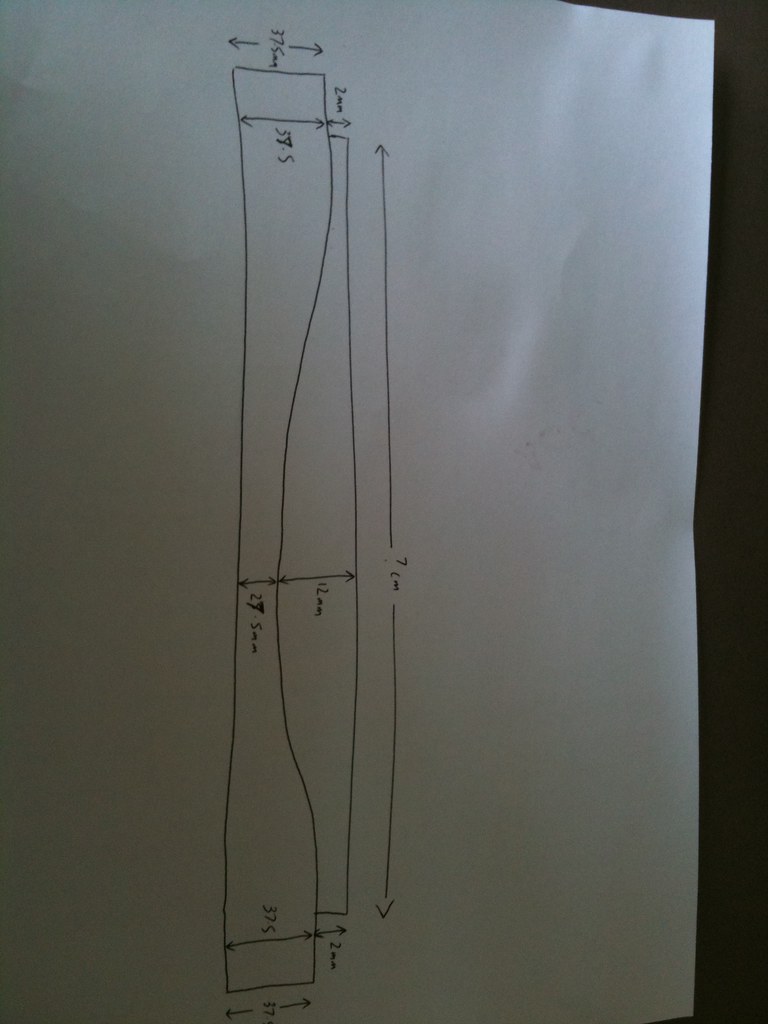

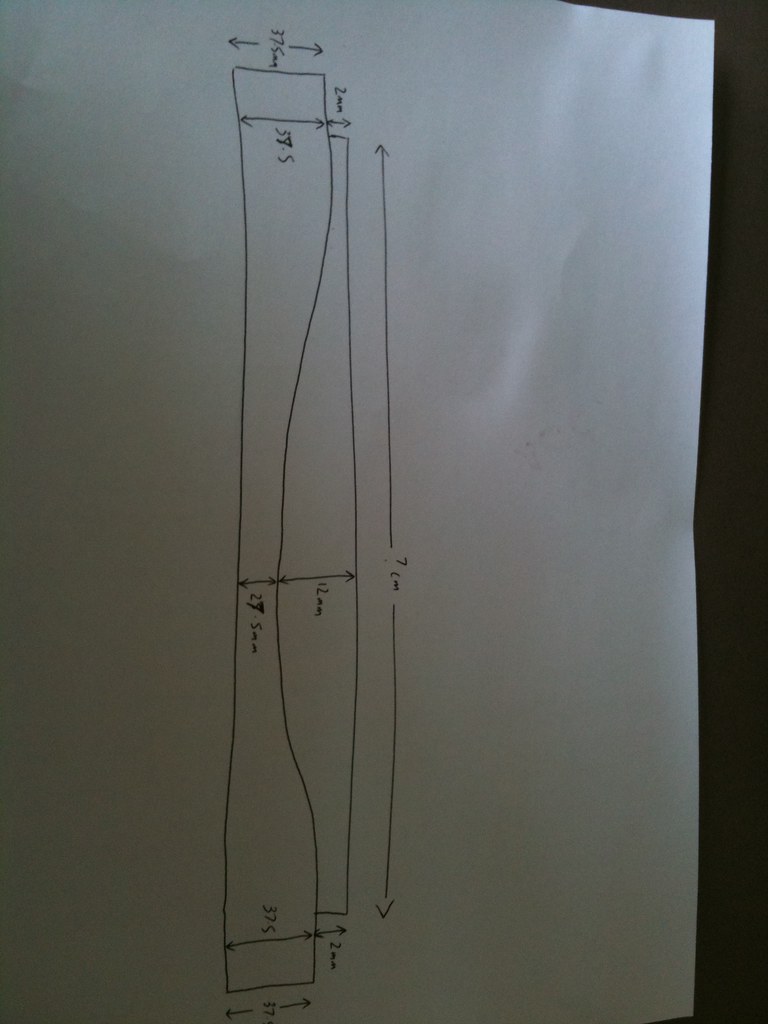

How does that look?

3500 cm radius

Do you guys think it will work well for planing?

Posted: Tue Aug 24, 2010 11:23 am

by chrismp

i guess the reason why nobody answered is that your crib design depends on many different factors such as ski length, width and most important the profile YOU want.

btw, what do you mean by 3500mm radius?

Posted: Tue Aug 24, 2010 12:15 pm

by SHIF

Why did you use a 3-D sketch to extrude the base?

Are you trying to have the core flex into this cavity while passing it through the planer so that both tapers are formed (tip and tail) simultaneously?

-S

Posted: Tue Aug 24, 2010 12:58 pm

by ben_mtl

I believe he's trying to make a crib like Iggy has done @ ON3P... A few passes through a planer and you're done on the cores... well, almost.

Posted: Tue Aug 24, 2010 3:06 pm

by twizzstyle

SHIF wrote:Why did you use a 3-D sketch to extrude the base?

Are you trying to have the core flex into this cavity while passing it through the planer so that both tapers are formed (tip and tail) simultaneously?

-S

Yes. It's a great way to plane cores. We do something similar but have a flexible board and these spacer blocks... its complicated, it would be MUCH nicer if we could get CNC'd boards like this.

a.badner - I'm just curious, how much were they going to charge you to machine this?

Posted: Tue Aug 24, 2010 3:34 pm

by a.badner

twizzstyle wrote:SHIF wrote:Why did you use a 3-D sketch to extrude the base?

Are you trying to have the core flex into this cavity while passing it through the planer so that both tapers are formed (tip and tail) simultaneously?

-S

Yes. It's a great way to plane cores. We do something similar but have a flexible board and these spacer blocks... its complicated, it would be MUCH nicer if we could get CNC'd boards like this.

a.badner - I'm just curious, how much were they going to charge you to machine this?

- Well they said they will take %50 off of materials and they said that any maching will be 20 - 50 dollars.

And about the Iggy from on3p i didnt know that they made this kind of crib until Rowen from on3p - ( alias name on newschoolers ) told me that they make inverse planing cribs on solid works and get them cnc'ed.

And I know my solid works performance is not the greatest because i am still in highschool ( gr 11 honors student ) and i am just starting the ski building thing, and i think im really doing good as of right now, i have a frame built already, and im starting my moulds this weekend. ( the CNC guy dded me over with the molds but for the crib he said that he could do it for cheap. )

i might start a journal, i dont know,

and one have a 6'' inch layflat bladder ? ... or fire hose?

The guy at the firehouse didnt want to give me an old one because if i get hurt he is reliable for it. Bullshit. i hate being so young.

Posted: Tue Aug 24, 2010 3:40 pm

by a.badner

chrismp wrote:i guess the reason why nobody answered is that your crib design depends on many different factors such as ski length, width and most important the profile YOU want.

btw, what do you mean by 3500mm radius?

uhm, i mean the arc that i extruded the profile with has a 3500 cm radius

Posted: Tue Aug 24, 2010 3:57 pm

by MontuckyMadman

is 1.5inch or whatever the metric equivalent is, MDF a special order thickness? They don't have that stuff at the lumber yard round here.

Posted: Tue Aug 24, 2010 5:19 pm

by SHIF

a.badner wrote:...i am still in highschool ( gr 11 honors student ) ...

Wow, you're about the youngest ski builder in this little club, I'm impressed. Definitely start a web journal to post your progress.

-S

Posted: Tue Aug 24, 2010 5:39 pm

by a.badner

MontuckyMadman wrote:is 1.5inch or whatever the metric equivalent is, MDF a special order thickness? They don't have that stuff at the lumber yard round here.

No, its just on one inch thick MDF, 2.54 cm. You can buy it at RONA, wait thats just in Canada. but they have it

And being the youngest Ski builder? i dont know, ive see some younger people on here, not really doing anything ( as in building wise ) but ya.

and about starting a journal. i guess i take pics of my tools and templates for the mold. that all i have done as of now. but i started the project about a week ago so, i guess i'm preetty far along.

And in my opinion you dont see as many kids on ski builders because the ones that can actually afford all of this just buy ski at the stores. Im only starting this with no help from my parents ... money wise and equipment wise, and im already broken. i bought a refurbished router, 13 inch planer, a refurbished jig saw, and few more things, and all that already costed about 600$ so there goes my first pay check of the summer.

And for steel, im lucky enough for my father to be working at a starter and alternator rebuilding and manufacturing place called RCP. i think they have a website? but hes the plant manager, so any scrap steel thats usable ( i.e steel beams, wire ect ) i'm allowed to use.

Posted: Tue Aug 24, 2010 5:45 pm

by falls

I don't think using an arc is the way to go with this method.

What you want to do is determine exactly what you want your core to look like (ie. length, tip and tail thickness, mid area thickness and the rate at which it tapers from the middle to the tips). If you do this then draw it on solidworks you can then turn it upside down and recess it into your piece of MDF. This creates the exact inverse of your core so when it goes through the planer you keep taking off parallel layers of wood until you are down to the correct tip thickness.

The actual shape of the core is the whole art of ski building. It depends as the others have said on ski length, width, wood type, desired flex pattern (soft/stiff) etc.

Mostly a good starting point seems to be 12mm under foot and 2mm at the tips, but the way you taper it from the middle to the tips has a huge amount to do with the final flex pattern.

This is a quick sketch of what you might be looking at doing, but you will need to add the details like ski core length and the arcs/splines used to determine your flex pattern.

Posted: Tue Aug 24, 2010 5:57 pm

by a.badner

falls wrote:

The actual shape of the core is the whole art of ski building. It depends as the others have said on ski length, width, wood type, desired flex pattern (soft/stiff) etc.

two things, i thought using an arc would be better than the spline idea you showed above, because looking at my twin tips i'm using right now the ( dynastar trouble makers) use a circular core for torsional rigidity. <- they used to advertise it as that.

And the second thing is, what time is it in Australia?

and di you just draw that?

drawing the spline isn't much work, ill draw one up and ask you again.

Posted: Tue Aug 24, 2010 6:33 pm

by MontuckyMadman

a.badner wrote:

what time is it in Australia?

You see its tomorrow over there so he's in the future. He knows what you are going to ask before you know.