Everything is ready to be pressed but it will be a few weeks before I get to it.

I wanted to post a few pics with some helpful tips.

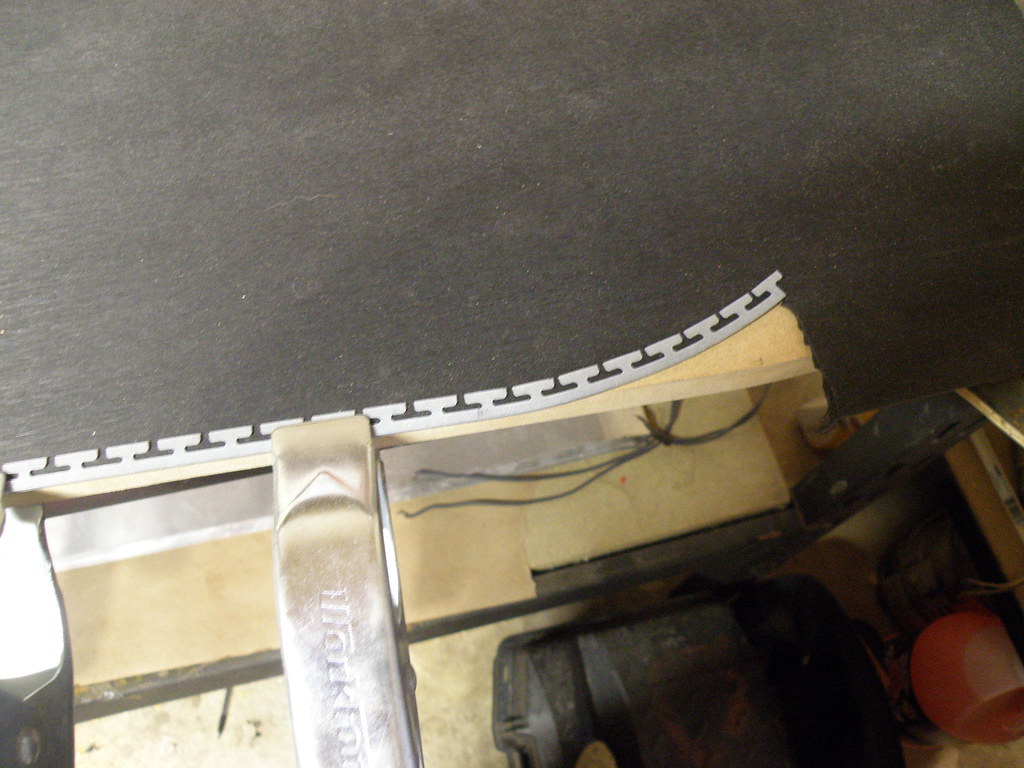

First is edges. Make sure they fit before you glue them.

There is no glue on that edge. Also notice where the edge is cut off. To get the fit I trace the edge with a mechanical pencil and then cut the base to the right size.

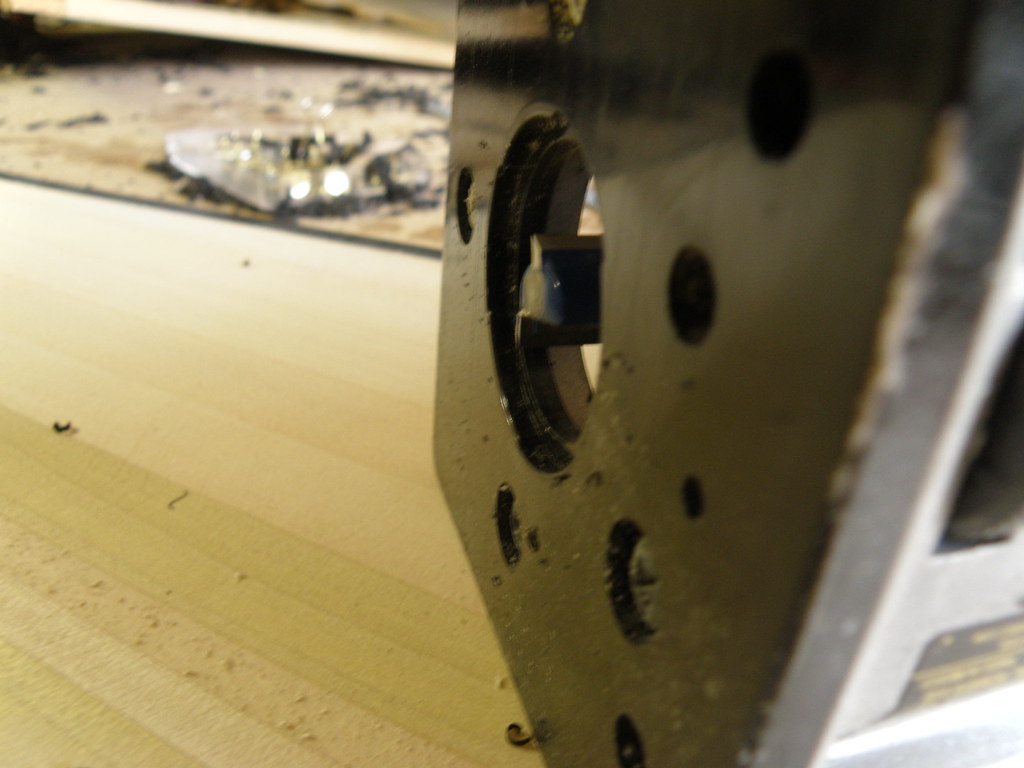

Rabbiting for the edge.

The bit is set for the right depth of the edge. I make a few test cuts too make sure it's right, and then I eyeball it along the length of the core. It's really easy to follow the sidewall, and if you do get off it's really not a big deal.

Prepping the material.

Base with two strips of black vds for the running length of each edge. 4 squares of natural vds for the contact point and end of the edge attachment. 4 strips of kevlar biaxial tape for reinforcement of the edges where the bindings will be.

Core prep:

Core with carbon fiber strips through the rocker point and the tip and tail. Carbon fiber pads that the inserts get mounted through. VDS squares for over the inserts and carbon fiber. VDS strips for above and below the sidewall.