sammer 2011/12

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

more progress from the dungeon...

Got the skis cut out and semi finished.

Even with the tip bender edges are still slightly out of plain.

Gotta work on cutting them to length better.

gluing edges running side down (traditional) edge fit is pretty good.

Once they get a proper base grind I'll post a better pic.

No camber just a flat spot under foot and rockered tip and tail.

Core to tip spacer transition turned out pretty tight.

Still gotta get a few coats of p/u on them.

I missed the mark with the frog, gotta mark out where the ski actually is on the mold, once the veneer is on the ski kinda disappears.

still all there but... oops

some details;

used 19oz triax 1 layer above and below the core,

some 22oz for binding mount,

3 24k carbon tow stringers above the core,

veneer is walnut with a skim coat of epoxy

Stained it after a bit of a sand with red oak stain.

Stained the maple sidewalls to see what it looked like

Small amount of heat 100f from my electric blanket, just to get everything curing.

All in all turned out OK.

Only minor cosmetic issues will definitely get those worked out for the next pair!

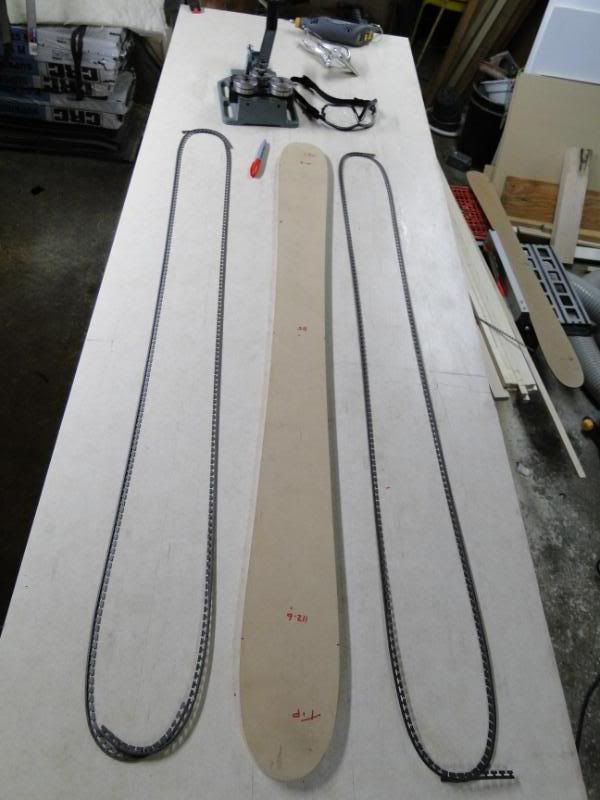

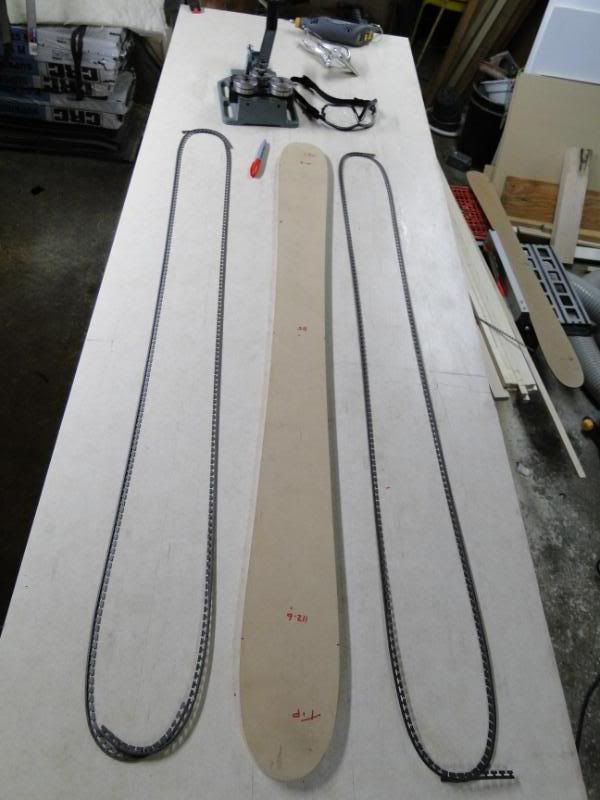

Got edges bent for the boys skis.

His cores will hopefully get sidewalls tomorrow.

Will probably use the orange base as tip spacer, it's pretty thick and abraded and treated both sides.

They're gonna have to be pretty thin at the tips and tails so should work out alright

To be continued...

sam

Got the skis cut out and semi finished.

Even with the tip bender edges are still slightly out of plain.

Gotta work on cutting them to length better.

gluing edges running side down (traditional) edge fit is pretty good.

Once they get a proper base grind I'll post a better pic.

No camber just a flat spot under foot and rockered tip and tail.

Core to tip spacer transition turned out pretty tight.

Still gotta get a few coats of p/u on them.

I missed the mark with the frog, gotta mark out where the ski actually is on the mold, once the veneer is on the ski kinda disappears.

still all there but... oops

some details;

used 19oz triax 1 layer above and below the core,

some 22oz for binding mount,

3 24k carbon tow stringers above the core,

veneer is walnut with a skim coat of epoxy

Stained it after a bit of a sand with red oak stain.

Stained the maple sidewalls to see what it looked like

Small amount of heat 100f from my electric blanket, just to get everything curing.

All in all turned out OK.

Only minor cosmetic issues will definitely get those worked out for the next pair!

Got edges bent for the boys skis.

His cores will hopefully get sidewalls tomorrow.

Will probably use the orange base as tip spacer, it's pretty thick and abraded and treated both sides.

They're gonna have to be pretty thin at the tips and tails so should work out alright

To be continued...

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

-

skidesmond

- Posts: 2337

- Joined: Tue Apr 07, 2009 3:26 pm

- Location: Western Mass, USA

- Contact:

Yeah really nice. I need my graphics to come out that clear.

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com

Thanks guys.

Frog is just printed on plain paper with my old inkjet printer. Cut out with an exacto knife.

Held in place with an epoxy skim coat.

You can see I actually sanded through the frog on his left back foot, and his right shoulder and thumb?

I think it's just a matter of picking the right colours to make them pop.

Tried printing on veneer yesterday but am out of blue ink and the veneer doesn't want to feed through the printer very well.

Might give it another try later.

sam

Frog is just printed on plain paper with my old inkjet printer. Cut out with an exacto knife.

Held in place with an epoxy skim coat.

You can see I actually sanded through the frog on his left back foot, and his right shoulder and thumb?

I think it's just a matter of picking the right colours to make them pop.

Tried printing on veneer yesterday but am out of blue ink and the veneer doesn't want to feed through the printer very well.

Might give it another try later.

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

shopvac... 19oz is vectorply E-TLX1900 I bought from headmonkey when he was getting out. Ya built a few pair with it now.

Same as the 22oz in the 45's but lighter in the 0 so using a bit of CF to make up the difference.

brazen... thanks I try

Need to work on the finishing, might try the pre-poly trick next time.

and skis are not quite like boards you can use 22oz and CF and still make a noodle ski if your core's too thin.

sam

Same as the 22oz in the 45's but lighter in the 0 so using a bit of CF to make up the difference.

brazen... thanks I try

Need to work on the finishing, might try the pre-poly trick next time.

and skis are not quite like boards you can use 22oz and CF and still make a noodle ski if your core's too thin.

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

thanks for the advice. We have used some triax from Raka that they sold us as "22 oz" with carbon fiber and they are pretty good for the flex. I don't know if the triax glass is actually 22 oz though or if it is heavier. It has a mat and it is pretty beefy. How much material do you actually weight to get the 22oz peice? Is is 1 yard by 1 yard or what? I am not sure I even have that much left so this might not be possible but I can do some math with a smaller piece if I know what I should multiply it up to. I think I have seen a post somewhere that describes the Raka 22oz as closer to 25 oz. Anyone done any real measurements with their glass?

1st of the boys skis are in the bag.

Had to go back to the old school for these.

Cores had to be pretty thin. He's a hard core skier but at 7 still pretty little.

Used the orange base as tip spacer so cores are down to close to 1.3mm and about 5mm at the waist.

Got materials all prepped last night

Cut out the first base and got it taped into the mold. Glued in core locators.

Like I said, going back to plastic sheeting and mastic tape.

He got a chance to do a tie-dyed fabric for the top sheet at a day camp this summer. Definitely one of a kind graphics one this pair!

If I managed to get all the air bubbles out you should be able to see the construction in the white parts of the fabric.

As these skis are full rocker I put a couple of carbon tows on top of the core.

Of course don't forget the frog

Cores are aspen with 1 maple stringer down the middle and maple sidewalls.

Used 19oz triax one layer below and above the core and a small piece of 22oz for binding mount.

EMV043/ECA032 I'm still not sure about that stuff, it's so thick even heating it took about 500 grams to get everything wetted out.

I think that's a lot!

I bought some EMV045 (should be a bit thinner) I'll try that soon.

Didn't want to experiment with something this important!

Just got a call from the boss, gave me the day off tomorrow so I might get the other ski done then.

More as things develop

sam

Had to go back to the old school for these.

Cores had to be pretty thin. He's a hard core skier but at 7 still pretty little.

Used the orange base as tip spacer so cores are down to close to 1.3mm and about 5mm at the waist.

Got materials all prepped last night

Cut out the first base and got it taped into the mold. Glued in core locators.

Like I said, going back to plastic sheeting and mastic tape.

He got a chance to do a tie-dyed fabric for the top sheet at a day camp this summer. Definitely one of a kind graphics one this pair!

If I managed to get all the air bubbles out you should be able to see the construction in the white parts of the fabric.

As these skis are full rocker I put a couple of carbon tows on top of the core.

Of course don't forget the frog

Cores are aspen with 1 maple stringer down the middle and maple sidewalls.

Used 19oz triax one layer below and above the core and a small piece of 22oz for binding mount.

EMV043/ECA032 I'm still not sure about that stuff, it's so thick even heating it took about 500 grams to get everything wetted out.

I think that's a lot!

I bought some EMV045 (should be a bit thinner) I'll try that soon.

Didn't want to experiment with something this important!

Just got a call from the boss, gave me the day off tomorrow so I might get the other ski done then.

More as things develop

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)