sammer 2011/12

Posted: Tue May 03, 2011 10:19 am

Haven't had too much time to work on skis these days.

Stupid work schedule takes up too much time.

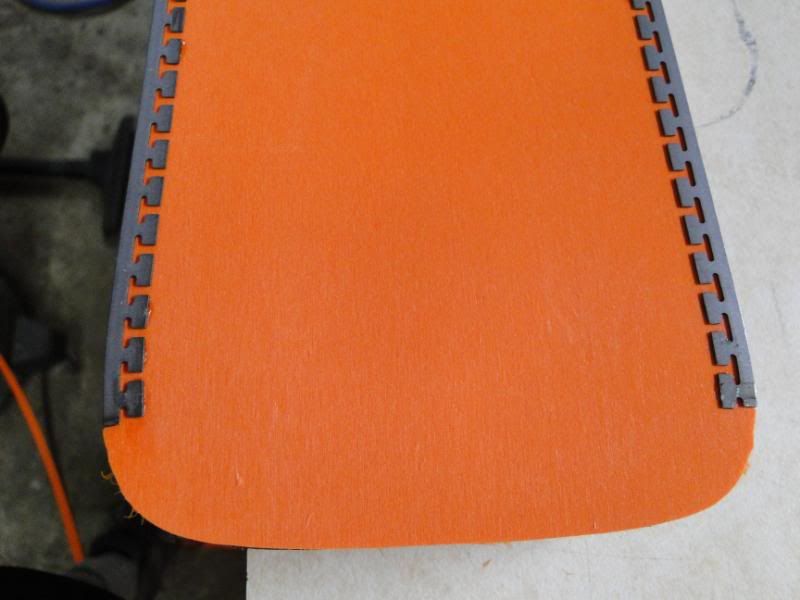

Did get some time this morning to make a couple of patterns though.

After trying a pair of armada arg's this winter decided that reverse/ reverse was definitely on the menu!

The boy needed something new as well!

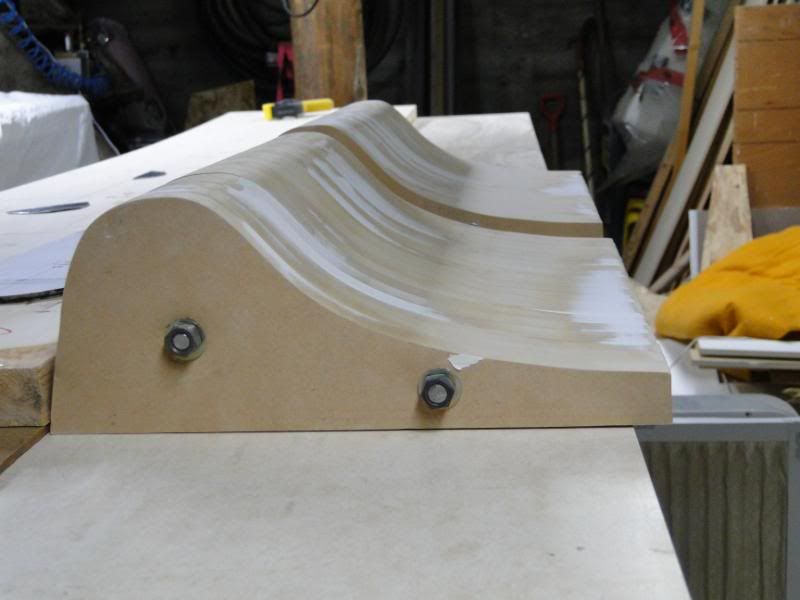

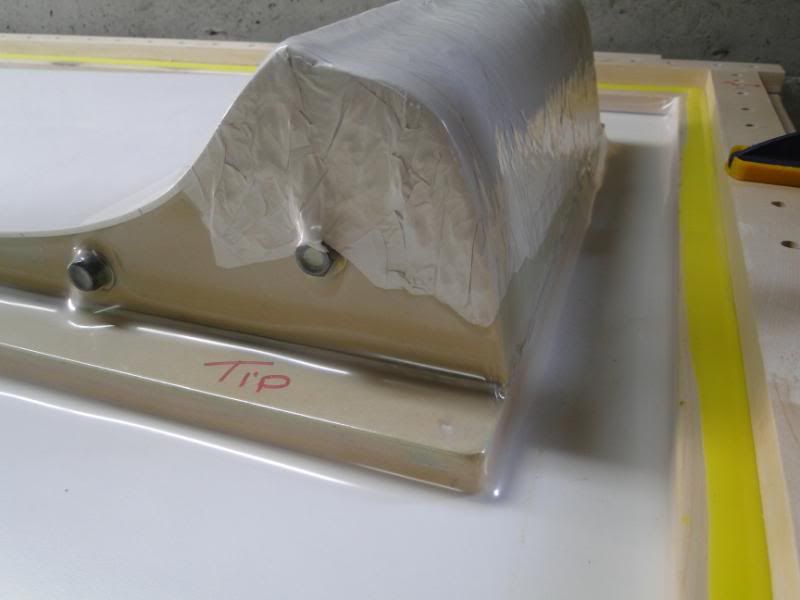

The big ones are a double sided pattern one side is reverse/reverse, the other is more like a JJ (20m? meter sidecut).

The little ones are 117cms should turn out to be 114-86-104

Reverse/reverse 186cms 126-132-135-128-119

Sidecut version 186cms 126-132-121-128-119

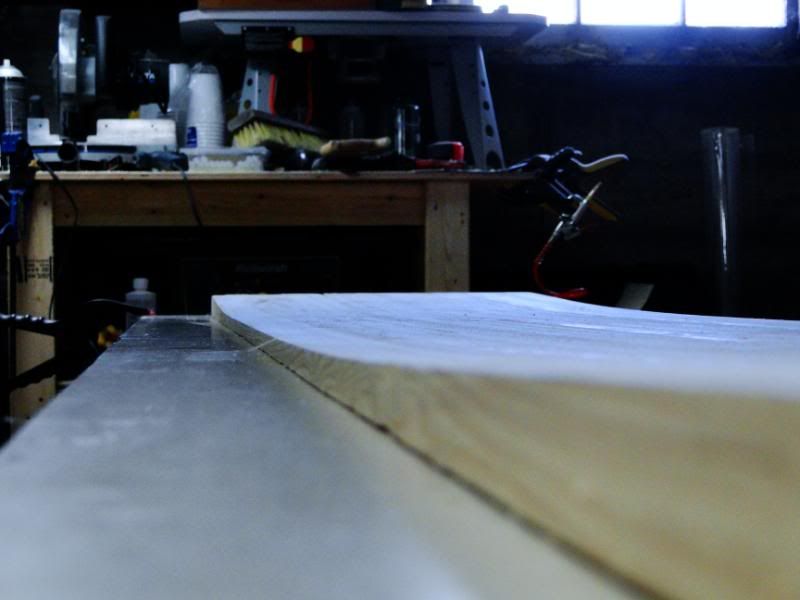

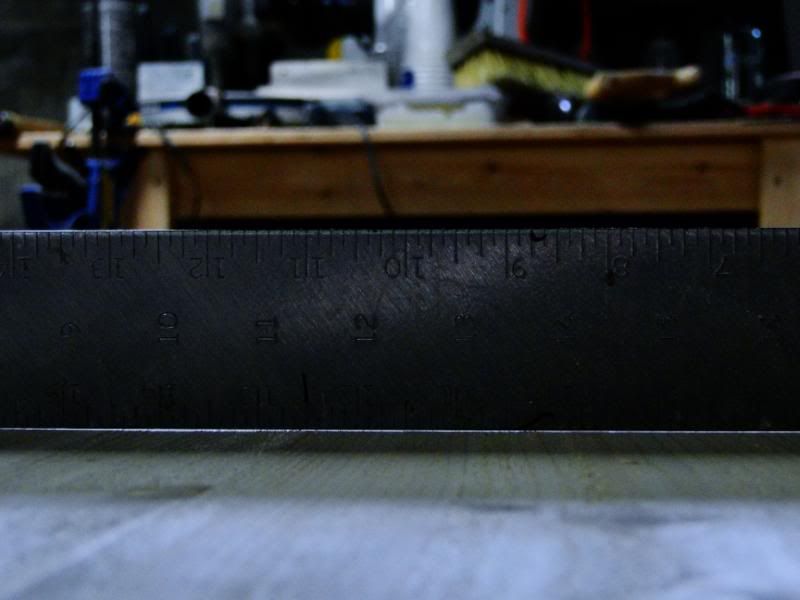

All will be rockered with flat camber.

Hopefully get some time to transfer these to actual templates soon.

will update as I progress.

sam

Stupid work schedule takes up too much time.

Did get some time this morning to make a couple of patterns though.

After trying a pair of armada arg's this winter decided that reverse/ reverse was definitely on the menu!

The boy needed something new as well!

The big ones are a double sided pattern one side is reverse/reverse, the other is more like a JJ (20m? meter sidecut).

The little ones are 117cms should turn out to be 114-86-104

Reverse/reverse 186cms 126-132-135-128-119

Sidecut version 186cms 126-132-121-128-119

All will be rockered with flat camber.

Hopefully get some time to transfer these to actual templates soon.

will update as I progress.

sam