Heat Mats

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

Heat Mats

Starting a journal on building a heat mat. This is the first Black mat that I have built, I really like the black, looks great! The size is 16X78 and 1400 watts @ 120VAC. The core of all mats I build is 7.5oz plain weave fiberglass.( Don't use chop strand!) The two part silicone that I use is a product of GP products of Dallas, Texas. Shore hardness of 25 and heat resitance to 500*f. The pot life time is 15-20 minutes and a cure time to touch in about 3 hours, fully cure 24 hours. More to come later with more pictures.

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

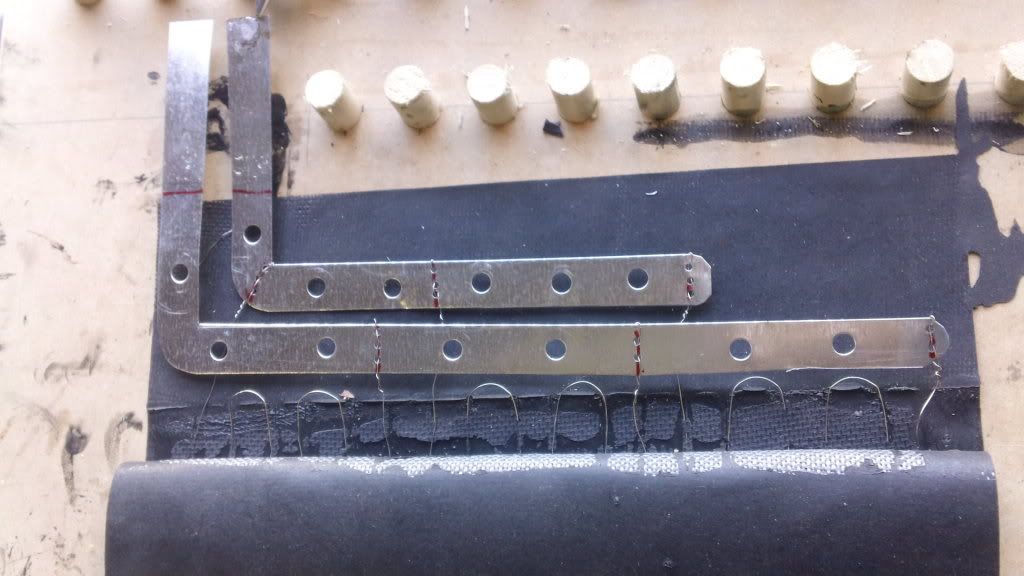

The mat is folded under so the nails wouldn't go through the mat. I have tried several ways not to put the nails through the mat and this seems to work. I'll silicone the top mat to the bottom mat in the middle first, then flip the ends out and silicone the ends, one more step but it makes for a better mat.gozaimaas wrote:how come you run the wires past the end of the mat?

clever method!

couple more questions if you don't mind

how much silicone do you use with the weight of glass you're using? do you let the wet out sheets of fiberglass cure first and then "glue" them together with silicone?

some photos of the connection of the resistance wires to the lead wires would be great as well!

couple more questions if you don't mind

how much silicone do you use with the weight of glass you're using? do you let the wet out sheets of fiberglass cure first and then "glue" them together with silicone?

some photos of the connection of the resistance wires to the lead wires would be great as well!

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

Keep your pants on!!! pictures are coming. I like the suspense. :)Yes, on this mat I'm going to glue two cured sheets together. What I do is over cut my fiberglass and the wet it out on some good flat and slick plates and put another plate on top of that, put everything in the vacuum bag and press. What I have done in the past is have my base layer done and cured then lay out the wires then cut another sheet of fiberglass and wet it out on top of the wires and base. But I couldn't really put it in the vacuum bag because of the nails. This time I built a plywood bed to build the mat on and then slide everything into the bag and press it. I'm going to build wooden caps out of some scrap to go over the nails so it doesn't poke a hole in the bag. For one heat mat it takes about 1.5Kg of silicone to get everything nice sealed up.chrismp wrote:clever method!

couple more questions if you don't mind

how much silicone do you use with the weight of glass you're using? do you let the wet out sheets of fiberglass cure first and then "glue" them together with silicone?

some photos of the connection of the resistance wires to the lead wires would be great as well!

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

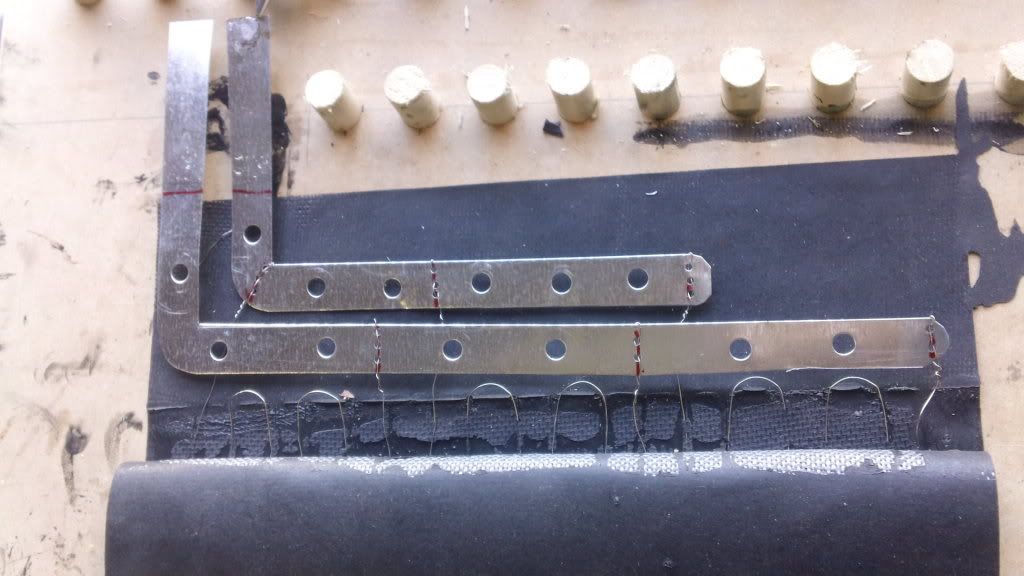

Here is another style of buss bar I made last night, I wanted the leads to come out of the end of the mat. 240 VAC, 2021 watts, 8.42 amps, 28.50 ohms

BTW, the holes are there for the silicone to have something to hold onto.

BTW, the holes are there for the silicone to have something to hold onto.

Last edited by troublemaker on Wed Oct 17, 2012 7:55 am, edited 1 time in total.

-

amidnightproject

- Posts: 378

- Joined: Wed Nov 04, 2009 10:59 am

- Location: Portland Area, Maine

- Contact:

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

Thanks!OAC wrote:Impressive! Honestly I haven't follow this heat mat making too close. What type of wires are you using?

The wire I use is Hot watts R-25 resistance wire (NiChrome), 2 ohms per foot. I got a great deal on it off of ebay this past spring, 2200' for $32. I called hot watts about some more they said 90 cents per foot!!!! Since then I have found another place that sells it by the pound. A pound of the correct gauge is around 8300' and $90 per pound. A typical heat mat has around 125' of wire in it.

Last edited by troublemaker on Wed Oct 17, 2012 7:56 am, edited 1 time in total.

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

Pretty much any size mat I build is $175. I dont do this to get rich or anything just enough to pay for materials and a lift ticket. I have built 12 mats so far and each time I run into something new.amidnightproject wrote:So when this blanket is all said and done. What does it cost for both material and labor?

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon