Bent Green Things 13/14

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

Possibly stupid question here chrismp, but how slow can your router spindle speed be set?

If the knife is on a bearing at the bottom, does it matter it the router is spinning?

Obviously it isn't ideal and you probably don't want it going at 4000rpm, but it may well still work if you can go slow enough.

The only issue may be the fact that it's weighted on one side, and while the knife is "in the air" it will cause vibrations.

If the knife is on a bearing at the bottom, does it matter it the router is spinning?

Obviously it isn't ideal and you probably don't want it going at 4000rpm, but it may well still work if you can go slow enough.

The only issue may be the fact that it's weighted on one side, and while the knife is "in the air" it will cause vibrations.

Hey Gang! I've got everything cut out, cores and bases are all lined up on the cassette. This will be my first bamboo core and they feel stiffer than my ash/poplar cores, granted these skis are fatter than my "normal" pair.

Ski shape is 180cm, 132-97-120, core: 2-12-2. 22oz tri-ax.

I'm thinking about adding some stringers of CF, I have 4.2 and 9oz CF. I like a fairly stiff ski and would appreciate it if anyone would care to give me some "Beta". *I will not hold you liable if the ski comes out to stiff or soft. ;-)

Ski shape is 180cm, 132-97-120, core: 2-12-2. 22oz tri-ax.

I'm thinking about adding some stringers of CF, I have 4.2 and 9oz CF. I like a fairly stiff ski and would appreciate it if anyone would care to give me some "Beta". *I will not hold you liable if the ski comes out to stiff or soft. ;-)

My latest two pairs of skis have very similar dimensions as yours and also have vertical laminated bamboo cores. I added Ipe sidewalls to both.

One pair has 10 oz unidirectional E glass and 12 oz biaxial carbon fiber on both sides of the core. These came out very soft but are rock solid in torsion. The next pair is identical but with added 9 oz uni carbon both sides (3" wide strips). These came out having a medium-stiff flex and are also rock solid in torsion. The biaxial carbon layers act like having metal in there. My next build will be similar but with full-width 4 oz uni carbon below the core and a 3" wide strip of 9 oz uni carbon above.

For your build I would suggest adding some uni carbon strips to stiffen the flex and also add some "pop" to the ride.

Also very important to create some shallow steps in the bottom of your cores to provide a space for the edge tabs to fit. This will yield much flatter bottoms than not having such steps. My skis tune up easily and have an edge to edge stone grind structure.

-S

One pair has 10 oz unidirectional E glass and 12 oz biaxial carbon fiber on both sides of the core. These came out very soft but are rock solid in torsion. The next pair is identical but with added 9 oz uni carbon both sides (3" wide strips). These came out having a medium-stiff flex and are also rock solid in torsion. The biaxial carbon layers act like having metal in there. My next build will be similar but with full-width 4 oz uni carbon below the core and a 3" wide strip of 9 oz uni carbon above.

For your build I would suggest adding some uni carbon strips to stiffen the flex and also add some "pop" to the ride.

Also very important to create some shallow steps in the bottom of your cores to provide a space for the edge tabs to fit. This will yield much flatter bottoms than not having such steps. My skis tune up easily and have an edge to edge stone grind structure.

-S

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

task completed! pulled them out, cut the flash, trued up the sidewalls. the only thing left to do is grind the bottoms and put a sidewall profile. I'm thinking about trying the strait bit with wedge technique instead of my dovetail bit.

My initial thought. Hardly any camber (let them cool under pressure in the press until 110F). they are softer than I was hoping but snappy as hell! I'm going to look into making a pair with Vectorply. I'm starting to wonder if my 22oz fiberglass (fiberglass supply) is sub-par? Don't get me wrong, they are great! and I'm totally excited to get them mounted up!

I'll get some photos up soon. Getting ready for the family first ski trip tomorrow. Then some night skiing on Thursday, when then storm comes in... I'm applying my Boston 1/3 weather rule to this one. Cheers all and happy new years!

My initial thought. Hardly any camber (let them cool under pressure in the press until 110F). they are softer than I was hoping but snappy as hell! I'm going to look into making a pair with Vectorply. I'm starting to wonder if my 22oz fiberglass (fiberglass supply) is sub-par? Don't get me wrong, they are great! and I'm totally excited to get them mounted up!

I'll get some photos up soon. Getting ready for the family first ski trip tomorrow. Then some night skiing on Thursday, when then storm comes in... I'm applying my Boston 1/3 weather rule to this one. Cheers all and happy new years!

Hey Gang,

pre-layup, new for this pair. alignment blocks and pins. can't say enough good things about this technique. My beer during the press was so much more enjoyable knowing they were in there:

"hot" out of the press:

one thing I noticed about this pair is the 9oz Carbon was noticeable in the base on the base grind (slightly noticeable in the top sheet). Do others see the same. One company (can't remember who) puts a rabbet down the center of the core to account for this. thoughts? I really don't like it and thinking about going back to 4oz or just doing thicker core.

the carnage! here is a photo of all the blades that I've tried. I bought a new jig saw for this year, a DEWALT DW331K, this thing is a serious horse compared to my old el cheepo skill:

for those of you with adjustable speeds, what speed do you run yours at?

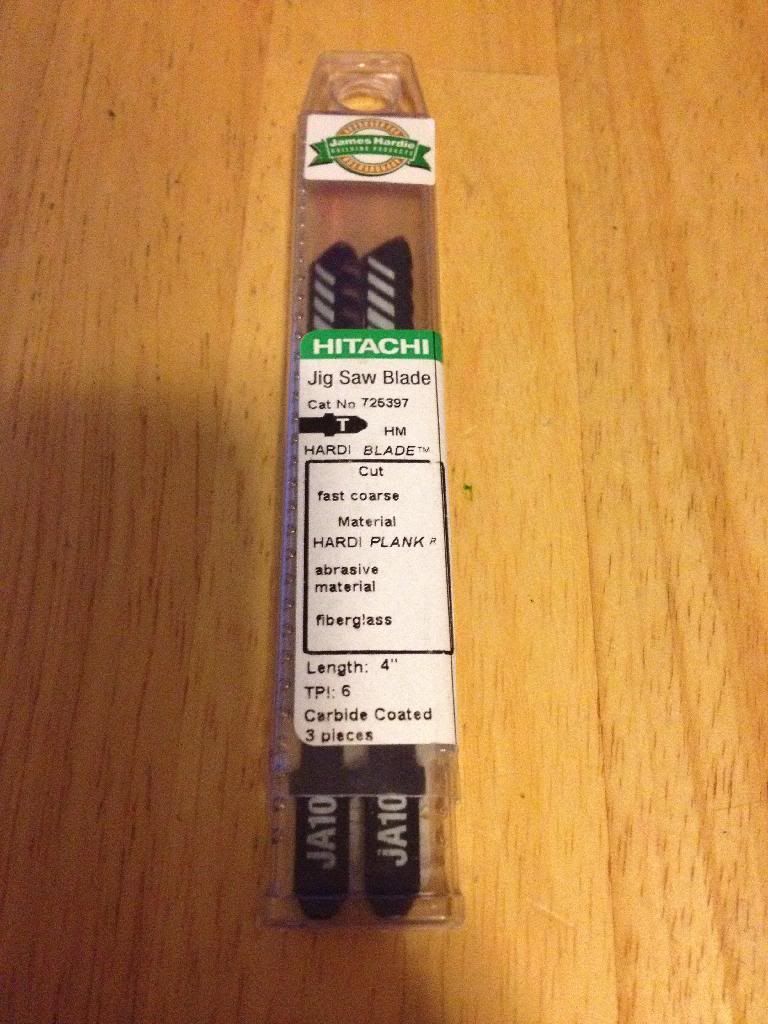

after SEARCHING my balls off, i now have no balls now... i ordered up some hitachi ja10 blades and they showed up today. I hope they last because man they were not cheep. They are made to cut fiber cement board, they should work. :-)

picked up some hardware, via Al's ski barn. great price:

they were mounted up yesterday. really excited to ski this pair.

pre-layup, new for this pair. alignment blocks and pins. can't say enough good things about this technique. My beer during the press was so much more enjoyable knowing they were in there:

"hot" out of the press:

one thing I noticed about this pair is the 9oz Carbon was noticeable in the base on the base grind (slightly noticeable in the top sheet). Do others see the same. One company (can't remember who) puts a rabbet down the center of the core to account for this. thoughts? I really don't like it and thinking about going back to 4oz or just doing thicker core.

the carnage! here is a photo of all the blades that I've tried. I bought a new jig saw for this year, a DEWALT DW331K, this thing is a serious horse compared to my old el cheepo skill:

for those of you with adjustable speeds, what speed do you run yours at?

after SEARCHING my balls off, i now have no balls now... i ordered up some hitachi ja10 blades and they showed up today. I hope they last because man they were not cheep. They are made to cut fiber cement board, they should work. :-)

picked up some hardware, via Al's ski barn. great price:

they were mounted up yesterday. really excited to ski this pair.