The 3M brand super 77 spray glue is about $30 a can in australia. I use a Selleys brand (local brand) that was about $10 a can. I think I will get about 20 or 30 pairs of skis out of the can. I hold the base with edges up in one hand and spray from about 15cm away in one stripe tip to tail down the centre, wait for it to go tacky and then stick it to the cassette. Make sure not to get any on the bonding surface as it doesn't mix well with epoxy.

This spray glue is commonly used in scrapbooking or crafts. It shouldn't be expensive.

You can sort of see the guy do it in this video at Moment skis at 8 min 50 seconds in. (just realised you linked the same video). I always think of it like I am holding up a large fish I just caught then spray a continuous line from tip to tail.

Jig saw blades I use a blade for metal - probably go through 1.5-2 blades per pair cutting out. I think the teeth are spaced about 1.5-2mm apart on the blade.

I'm not sure what you mean by a "separator" - do you mean mold release wax?

I wax the cassette aluminium with maguires mirror shine (

http://www.meguiars.com.au/mirror-glaze ... lease-wax/ or something like that. I apply it let it set up and buff off. Usually do 4 coats on the bottom cassette sheet and then buff to high shine at the end. I do this every time as I use the acetone to clean off the spray adhesive glue after a build and worry it also washes away my mold release.

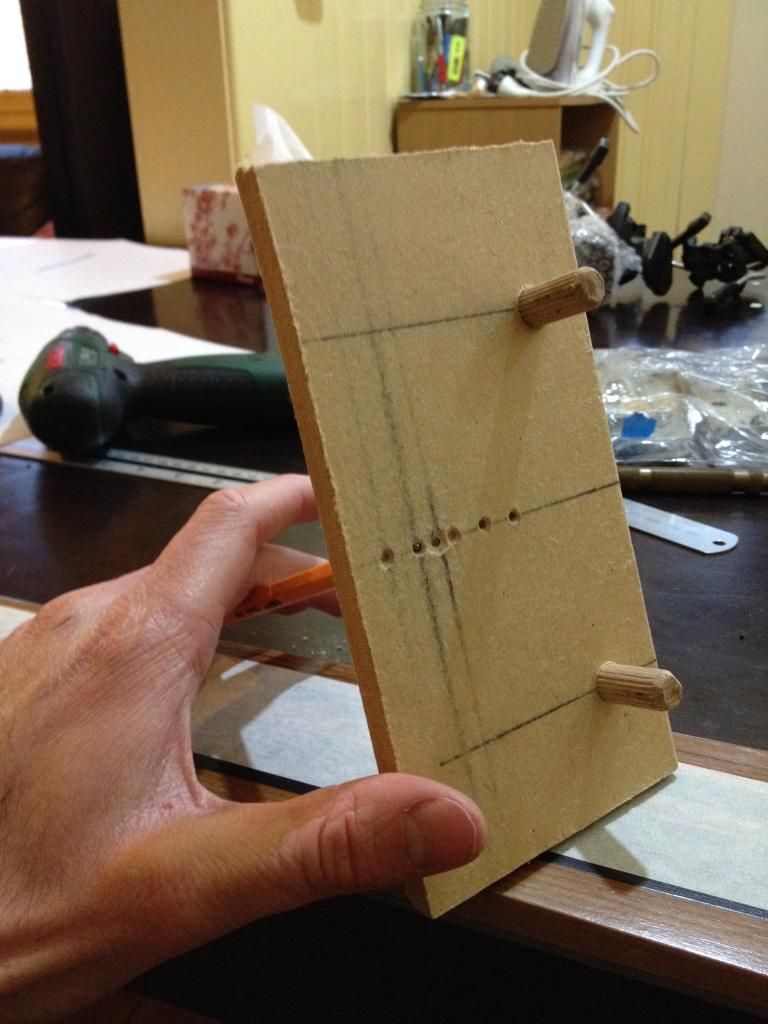

I have found the core allignment blocks stick to the aluminium fine even with mold release applied. The same is true for the spray adhesive. I wax the whole aluminium sheet and stick the base/edges down onto the waxed sheet, that way any epoxy that gets under the base won't stick to the cassette.

Hopefully that clears it up for you

Don't wait up, I'm off to kill Summer....

[/img]

[/img]