Page 1 of 1

why Paulownia?

Posted: Wed Sep 24, 2014 2:20 pm

by MadRussian

I'm trying to understand why Paulownia is most popular wood for ski core by big manufacturers.

wood Property numbers except for weight is not impressive

http://www.wood-database.com/lumber-ide ... paulownia/

if I didn't know it's widely used for skis and had choice of wood differently wouldn't pick Paulownia

Posted: Wed Sep 24, 2014 3:32 pm

by Dtrain

I've used it. It's just super light. Period. Strong for the weight....ya. But still weak as hell. It has nothing to do with the green aspect, though the stuff does grow right off the old stump if you cut one down.

It's because it's bought in huge amounts for next to nothing from overseas. I was quoted $700 us for 1 cubic meter of dimensional 1x6 planed boards.

I may be biased, but sitka spruce is the best ski wood there is based on strength to weight. That being said......use what's local to you.

Posted: Wed Sep 24, 2014 4:12 pm

by MadRussian

. I am trying to understand what big fuss about Paulownia. Because when reading description of the some skis on Internet Paulownia describe sometimes as next best thing after sliced bread when in reality it sounds more like snake oil

have no intention to use it. All wood I need to build skis grow locally

Posted: Thu Sep 25, 2014 1:14 am

by gozaimaas

I use it cause it grows here in AU and its seriously light. Mix with bamboo and wow

Posted: Thu Sep 25, 2014 2:26 am

by chrismp

I've used it in a few boards. Advantage is that it's really light, but I've also switched to spruce/fir (the European varieties) as it is readily available from a local sawmill that produces only hight quality boards and the strength to weight ratio is way better than paulownia.

Posted: Thu Oct 16, 2014 8:43 am

by 24Dave

If you haven't used it, I'd describe it as half way between poplar/aspen and balsa. I think it's a good conservative choice if you are entertaining thoughts of lightening cores with foam stringers, honeycomb, channeling or end grain balsa as part of your cores. It's notably soft, compressing easily under strong finger pressure even, but pretty stiff and has an even, fine grain and doesn't want to shear. It can be weird sanding large surface areas of it by itself or next to other woods. It can go wavy from the softer portions between rings or create dips between harder woods, so cutting tools to shape can be easier than sanding tools.

Posted: Fri Feb 27, 2015 11:39 am

by 24Dave

observation: I pressed a paulownia split at 50psi, 150 degrees f, 20 minutes laminating at room temp, 1 hr ramp time to 150. I laminated only the base. I noticed that next to the rings in the wood where the pores are larger, the resin had wicked all the way through to the deck up to 8mm thick parts of the core. Good for shear strength I imagine, might want to preseal if extreme lightness is the goal. Still really light skis or board halves.

Posted: Fri Feb 27, 2015 11:43 pm

by Dtrain

Pic, pics, pics. Not enough board porn on the site lately

Posted: Sat Feb 28, 2015 5:16 am

by Richuk

Great post Dave - thanks for sharing the info.

Posted: Wed Mar 11, 2015 10:14 am

by casmat

yes great post

!

almost kiteboards are made of paulownia and I have built enough of them to say that wood it's really stiff.......but I don't know how much is for a snowboard/ski.

for a 137/41 kiteboard 3-8-3 mm full paulownia core with 22 oz triax is stiff as 'ironing board'

my scares are to make full wood paulownia snowboard/ski cores could be too stiff..

what do you think??

for me it's quite impossible to get aspen wood

so I have to find other solutions..so paulownia could be one

peace

Posted: Wed Mar 11, 2015 10:40 pm

by gozaimaas

Stiff? Its soft and relatively flexible.

Posted: Thu Mar 12, 2015 5:35 am

by vinman

For the short length (137cm) of the kite board and combined with 22ox triax I would bet that it is stiff, especially when you factor in the amount of resin the wood is soaking up.

In a longer piece like a ski it might not feel quite as stiff.

Posted: Mon Sep 14, 2015 11:29 am

by 24Dave

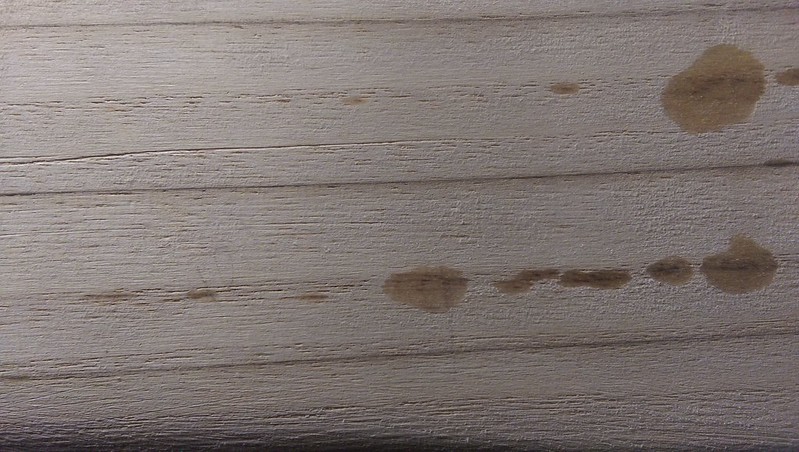

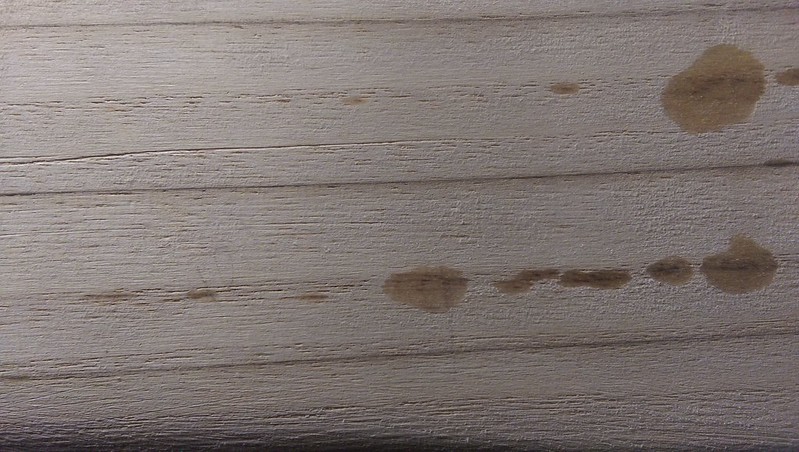

some pics of resin flowing through paulownia.

Have another board coming through where I press the base then profile and vacuum the top laminates on later. In this first photo you can see how resin flowed up through a 9mm portion of the core.

this second picture shows the resin flow up through 5mm in the top of the photo and tapering off at 10mm in the bottom photo, about the same as my last round of boards.

I'm still getting really light boards so I think I'll stick with the saturation rather than doing a fast curing precoat with something like resin research Quik Kick, but it would probably save a few ounces. If anything, it shows you don't have to sweat doing the best glue up job on your core strips