What pressure do you press at?

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

What pressure do you press at?

I'm trying to do an FEA analysis so we can properly select the beams for our press frame. the problem is I dont really know what the ideal pressure to press at is. I am using two 4" fire hoses that lay flat at about 6.5" each. Ive been modeling it at 70psi but is that too much? I tried searching and cant find anything.

I expect to press at 50 PSI.

And yeah, overbuilding = way to go. I am hoping what I'm putting together now is pretty overbuilt.

Just attached the top and bottom beams last night. Still need to add the legs and two support beams attached to each leg. Hopefully tomorrow night.

All the steal is 5"x5"x3/8" Steel (although the legs are the 5"x3"x1/4" steel). The bottom beams are 94" long, and there are (3) 10" long sections support sections connecting each beam. right now 8 Grade 8 bolts attach each section, so 32 bolts per side and 64 total bolts. I still need to attach the legs and a top/bottom support to the press. Hopefully tomorrow.

Each bolts goes bolt, washer, washer, lock washer, nut. I am going to go out tomorrow and see if I can find enough grade 8 nuts to double nut everything just in case. Dont know if that will happen as I would need close to 80 nuts, but I may just get some grade 5 nuts. I figure that it should be ok as it is just a secondary, back-up nut. Can anyone comment on this?

In total, I will have used 148 grade 8 bolts. Eventually I want to add two supports sections that enclose the press as well, but don't have the extra funds at the moment. When I am finally done I will post all about it.

Pic of the legs with just the bottom supports attached. There is also a 36" wide base w/ casters and also a 16" wide beam attached on the top.

guess we'll find out how it works in a few weeks

And yeah, overbuilding = way to go. I am hoping what I'm putting together now is pretty overbuilt.

Just attached the top and bottom beams last night. Still need to add the legs and two support beams attached to each leg. Hopefully tomorrow night.

All the steal is 5"x5"x3/8" Steel (although the legs are the 5"x3"x1/4" steel). The bottom beams are 94" long, and there are (3) 10" long sections support sections connecting each beam. right now 8 Grade 8 bolts attach each section, so 32 bolts per side and 64 total bolts. I still need to attach the legs and a top/bottom support to the press. Hopefully tomorrow.

Each bolts goes bolt, washer, washer, lock washer, nut. I am going to go out tomorrow and see if I can find enough grade 8 nuts to double nut everything just in case. Dont know if that will happen as I would need close to 80 nuts, but I may just get some grade 5 nuts. I figure that it should be ok as it is just a secondary, back-up nut. Can anyone comment on this?

In total, I will have used 148 grade 8 bolts. Eventually I want to add two supports sections that enclose the press as well, but don't have the extra funds at the moment. When I am finally done I will post all about it.

Pic of the legs with just the bottom supports attached. There is also a 36" wide base w/ casters and also a 16" wide beam attached on the top.

guess we'll find out how it works in a few weeks

-

heliski989

- Posts: 117

- Joined: Sat Jan 27, 2007 8:29 pm

- Location: Denver, CO

- Contact:

eh

That looks like it should hold, all tho you are using the steel in a way that it is not designed to be used. you would be in much better shape if you were to use the square tubing in a vertical way. for the amount of $$ you have spent on bolts you could have taken the press to a welder and made it fail safe. you have a good idea with all the grade 8 bolts, they are very strong. grade 5 are sometimes a better bet tho, they will strech and bend... wihch gives you some warning before they fail. grade 8 just snap! i can help you out with a design if you need help. i have quite a fue years of welding and fab experince.

Re: eh

Yeah, I would actually still possibly like to get it welded. Don't know if I would need to haul it somewhere, or just get someone to come by and weld it. The reason I went with bolts for the time being, though, is that I am currently a college student and my housing situation varies year to year. My current lease runs up in May, so unless I find a new place close enough to transport it there on the street (which I am sure would be an adventure in itself) I will need to take it apart again and move it.

There are a number of things I would change on it if I could go back and redo it, but once things got going I sort of got locked in to where I am.

I have been thinking about getting a few pieces welded that would still allow me to easily move the press, like the 3 beam support connectors and possibly the two top and bottom beams (although moving almost 500 lbs wouldn't be super fun). We'll see. I am just taking it as I go right now.

I already have had thoughts of making another press in the future and could always use some more help.

If you have an comments on the current press which you think would be good improvements, by all means let me know (on here or thru PM). The beefier the better. I just need to be able to move it from place to place.

There are a number of things I would change on it if I could go back and redo it, but once things got going I sort of got locked in to where I am.

I have been thinking about getting a few pieces welded that would still allow me to easily move the press, like the 3 beam support connectors and possibly the two top and bottom beams (although moving almost 500 lbs wouldn't be super fun). We'll see. I am just taking it as I go right now.

I already have had thoughts of making another press in the future and could always use some more help.

If you have an comments on the current press which you think would be good improvements, by all means let me know (on here or thru PM). The beefier the better. I just need to be able to move it from place to place.

-

heliski989

- Posts: 117

- Joined: Sat Jan 27, 2007 8:29 pm

- Location: Denver, CO

- Contact:

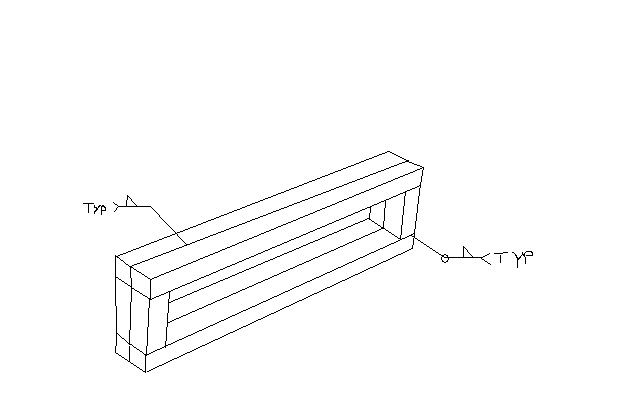

kinda crude

sorry about the quality, i whipped it up in 3 min at midnight

as i said before you should arange you legs on the press verticaly as i ahve shown in the pic

as i said before you should arange you legs on the press verticaly as i ahve shown in the pic

learn something new everyday....

I will keep that in mind if I ever make another press. It would require everything to be welded together, so I would need a permanant place to live before I would want to do that. But I will keep that in mind. I like the idea of square tubing as the connectors more than pieces of I-beam. I feel like they will flex much less. Correct me if I am wrong...

I will keep that in mind if I ever make another press. It would require everything to be welded together, so I would need a permanant place to live before I would want to do that. But I will keep that in mind. I like the idea of square tubing as the connectors more than pieces of I-beam. I feel like they will flex much less. Correct me if I am wrong...

-

heliski989

- Posts: 117

- Joined: Sat Jan 27, 2007 8:29 pm

- Location: Denver, CO

- Contact:

with your situation in mind i believe that you have a good design. there should be no problem with strength, especially if you are just going to use one hose at a time. you shouldn't be generating more than 30,000 lbs of pressure. that setup should be fine. just be carefull. have you got a bladder yet? if not i will send you some pics of the way i set mine up, no leaks and was really easy to build. Good luck

Yea Ive read enough posts on here about breaking presses to know to over design. Right now modeled at 70psi across the entire bottom surface of the beams (which is a worst case load area) Im getting 1.2 factor of safety. My goal is to keep beefing up the beams until I get atleast a FOS = 3. I'm also modeling it as if the end supports and the top and bottom beams were completley fix together. i didnt want to spend the time to model the bolts and everything. Ill have to maek sure to bolt the crap out of it to make sure its strong.

I'll post pics of the FEA once i get it to pass.

thanks for the help.

I'll post pics of the FEA once i get it to pass.

thanks for the help.

i have been running mine at 90 psi. it really depends on the distance your

bladders have to inflate to contact the board. mine is set up at about 2"-2.5" so it really is not 90 psi due to the decreased surface area pressing on the board.

iggy,

press looks really good. if you need something welded in the future

let me know. wouldn't take too long for you to drive down. looking forward to seeing your skis.

jason

bladders have to inflate to contact the board. mine is set up at about 2"-2.5" so it really is not 90 psi due to the decreased surface area pressing on the board.

iggy,

press looks really good. if you need something welded in the future

let me know. wouldn't take too long for you to drive down. looking forward to seeing your skis.

jason

we decided not to go with a prenaumatic press. its also not exactly a clamp press either. and its not a vacuum press. We needed to use steel girders to prevent bending. and it does involve bolts.. alot of bolts. over 30 bolts... but its been perfect for us. its also heated.

so to answer the topic question:

we dont really know how much pressure.. put it this way if we wanted to we could easily crush any type of wood. we oviously dont press at that tho. i have never sat down and worked out how to measure it.

i will post some pics soon when i document the next ski build.

schuss

so to answer the topic question:

we dont really know how much pressure.. put it this way if we wanted to we could easily crush any type of wood. we oviously dont press at that tho. i have never sat down and worked out how to measure it.

i will post some pics soon when i document the next ski build.

schuss

SCHÜSS 2011

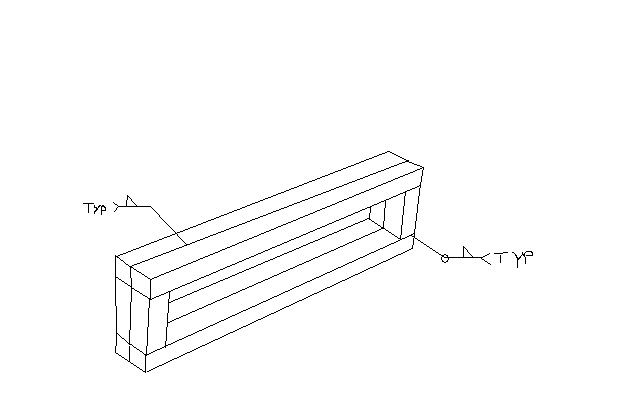

Figured since I included some pics above I may as well add how my press it shaping up. Still need to add two 16" wide 5"x5" steel tubing, and I believe I am going to add 2 more central supports, each 1/3 in from the side, but it is shaping up pretty nicely.

Just the top and bottom beam are held together on each side by 32 grade 8 bolts, plus there are a bunch more in the supports. Since I am pressing with only one hose, I believe this is going to be more than adequate. Presses like Graf's seem to only be held on to with 16 bolts per side, and they are using two hoses or one fat hose. Can't wait to test it out....

Just the top and bottom beam are held together on each side by 32 grade 8 bolts, plus there are a bunch more in the supports. Since I am pressing with only one hose, I believe this is going to be more than adequate. Presses like Graf's seem to only be held on to with 16 bolts per side, and they are using two hoses or one fat hose. Can't wait to test it out....