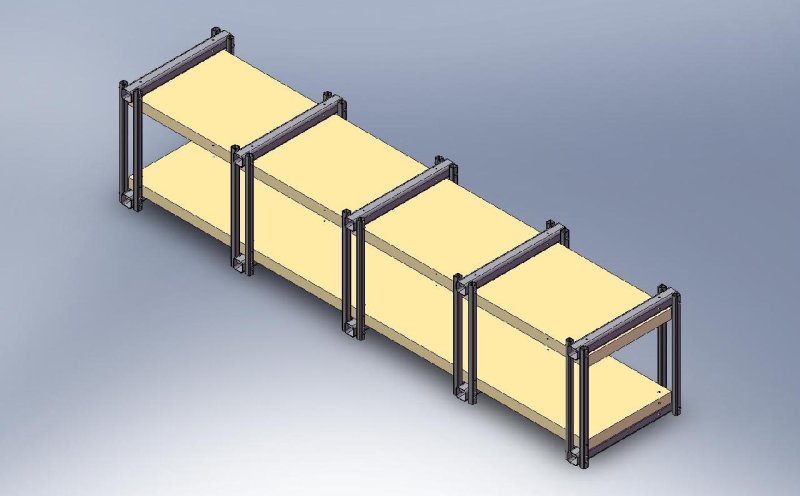

The idea is quite simple. I have opted for a design which is similar to the one detailed in the tutorial section of this website;

I have attempted to use less metal. In my eyes the long lengths of metal used in this design could quite happily be replaced by wood as you are not using the box section steel to it's full advantage.

My design consists of 5 bracing sections, though I may use 7. I think that it is important to use an odd number of braces in a design such as this as the most deflection in the frame will occur at the center of the frame. Using an odd number of braces will mean that there will be central support on the frame to prevent these deflections.

Each brace consists of a 50x50x2.5mm horizontal section at the top and bottom. These are vertically joined by a pair of 25x25x3mm pieces of box section on either side. The braces each have 12mm holes in them. Through those holes a 12mm pin will be pressed as there will be an interfearance fit between the pin and the hole. The brace section can then be trued and MIG welded together ensuring that the joins will be able to withstand many tonnes of pressure.

The braces will be drilled and tapped with M6 holes and a 50mm thick strip of MDF will be bolted down onto the cross braces using countersunk M6x55mm hex head bolts. I chose MDF instead of the box section because it should be stiff enough providing there is the correct ammount of bracing accross it and the braces are all evenly spread. Precision is everything! It will also cost less than using box section steel.

I am in the process of getting hold of either 2 lengths of 6" diameter fire hose or 1 length of 12" diameter fire hose, dpending on cost and the specification of the hose my supplier can provide me with.

I have preformed some FEA reports on the individual cross braces and with 85psi of force on the upper and lower horizontal sections of the braces there will be approximately 2mm of deflection. I think to reduce the ammount of deflection the 25mm vertical braces should be replaced with 50mm tubing as they appear to flex inwards causing the upper braces to deflect. However computer testing is no substitute to the real thing, so I need to order some materials!

Any input would be gratefully recieved as this is my first press design